Go To Table of Contents

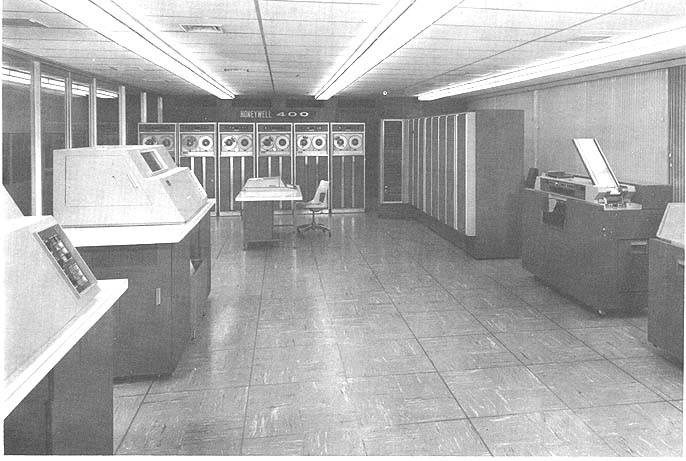

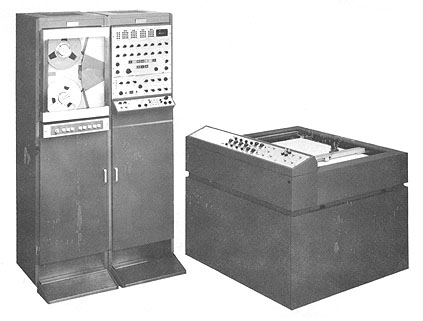

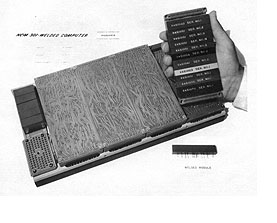

| BRL 1964, HONEYWELL 400, starting page 0116

|

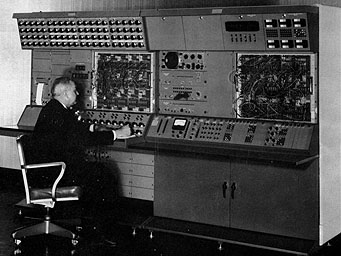

HONEYWELL 400

MANUFACTURER

Minneapolis-Honeywell Regulator Company

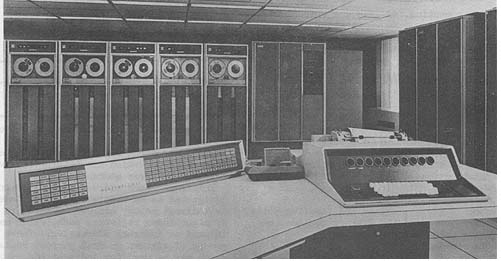

Photo by Minneapolis-Honeywell

APPLICATIONS

General purpose scientific and engineering computing. General purpose

business data processing. Real-time applications.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 + 2 check bits

Decimal digits/word 12 + 2 check bits

or 11 + sign + 2 check bits

Alphanumeric chars/word 8 + 2 check bits

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 63

Arithmetic system Fixed and floating point

Floating point is standard by sub-routine; optional by built-in hardware.

Fixed point is standard.

Instruction type Three address

Number range

48 binary digits, 12 decimal digits, 11 decimal digits + sign

Instruction word format

+---------+---------+-----------+-----------+

| 1 12 | 13 25 | 26 38 | 39 48 |

+---------+---------+-----------+-----------+

| Command | Address | B Address | C Address |

| Code | | | |

+---------+---------+-----------+-----------+

The command includes 6-bit operation code and 6-bit index register

designation.

Automatic built-in subroutines

Automatic subsequence on error conditions.

Extensive editing instructions.

Automatic coding

EASY-Assembly System

COBOL-Business Compiler

AUTOMATH-Scientific Compiler (FORTRAN II compatible)

Sort-Collate Routines

Scientific Library

Input/Output Package and Report Editor

PERT

Run Monitor

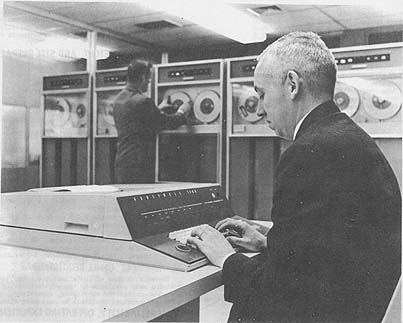

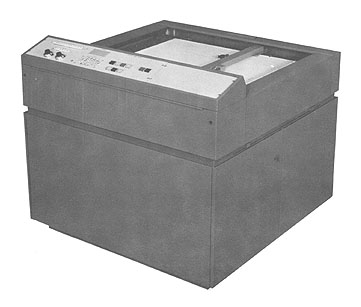

Photo by Minneapolis-Honeywell

APPLICATIONS

General purpose scientific and engineering computing. General purpose

business data processing. Real-time applications.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 + 2 check bits

Decimal digits/word 12 + 2 check bits

or 11 + sign + 2 check bits

Alphanumeric chars/word 8 + 2 check bits

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 63

Arithmetic system Fixed and floating point

Floating point is standard by sub-routine; optional by built-in hardware.

Fixed point is standard.

Instruction type Three address

Number range

48 binary digits, 12 decimal digits, 11 decimal digits + sign

Instruction word format

+---------+---------+-----------+-----------+

| 1 12 | 13 25 | 26 38 | 39 48 |

+---------+---------+-----------+-----------+

| Command | Address | B Address | C Address |

| Code | | | |

+---------+---------+-----------+-----------+

The command includes 6-bit operation code and 6-bit index register

designation.

Automatic built-in subroutines

Automatic subsequence on error conditions.

Extensive editing instructions.

Automatic coding

EASY-Assembly System

COBOL-Business Compiler

AUTOMATH-Scientific Compiler (FORTRAN II compatible)

Sort-Collate Routines

Scientific Library

Input/Output Package and Report Editor

PERT

Run Monitor

| BRL 1964, HONEYWELL 400, starting page 0117

|

Registers and B-Boxes

Three Index Registers are standard.

ARITHMETIC UNIT

Average Time Incl.

Stor. Access

Microsec

Fixed Decimal Add 111.0

Fixed Decimal Multiply 1,591.0

Fixed Decimal Divide 5,574.0

Fixed Binary Add 101.8

The above times are for the three-address operation

A + B -> C etc. (11 decimal digits, operands + sign

Arithmetic mode Parallel

Timing Asynchronous

Operation Sequential

Tape read-write overlap

Print run can be performed simultaneously with another program without

special programming.

Simultaneous processing and program interrupt facilitate real time

operation.

STORAGE

No. of No. of Access

Medium Words Digits Microsec

Magnetic Core 1,024 12,285 9.25

to 4,096 to 49,152

Magnetic Disk 600,000,000 (Max) 1,180 (Avg)

Magnetic Tape

No. of units that can be connected 16 Units

No. of digits/linear inch 1,110 Digits/inch

Channels or tracks on the tape 10 Track/tape

Blank tape separating each record 0.66 Inches

Tape speed 120 Inches/sec

Transfer rate decimal digits/sec 133,000 Digits/sec

Cross gap time 5.55 Millisec

Average time for experienced

operator to change reel of tape 20 Seconds

Physical properties of tape

Width 0.75 Inches

Length of reel 2,500 Feet

Composition

Mylar base with oxide coating.

Vacuum techniques used to mount reel, drive, stop and control tape.

Error detection and correction by orthotronic control.

Variable length records.

Other tape units operating at 48,000 and 96,000 decimal digits/second are

available.

INPUT

Medium Speed Remarks

Card Reader 800 cards/min (Card buffer avail)

Paper Tape Reader 500 or

1,000 frames/sec (5,6,7 or 8 channel

Ortho-scanner 1,500 doc/min

The scanner reads Honeywell ortho-bar code, rejection rate is less than

0.1°%.

Optical-scanner 196, 240 or 312 doc/min Real-Time Input

Varies with circuit facilities on toll or leased wire circuits.

OUTPUT

Medium Speed

Card Punch 250 cards/min

Printer 900 lines/min

Paper Tape 110 frames/sec

Real-Time Output

Varies with circuit facilities on toll or leased wire circuits.

Buffered console keyboard and printer are standard. Simultaneous peripheral

processing. Program interrupt and priority processing.

CHECKING FEATURES

Fixed:

Memory Parity (2 parity bits/word)

Internal Logic

Card Reader hole count and data validity.

Card Punch hole count and data validity.

Printer echo check and data validity.

Magnetic Tape and disk orthotronic detection and correction.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 24.2 KVA

Area, computer 700 sq ft

Floor loading 75 lbs/sq ft

Capacity, air conditioning 5 Tons

Site preparation requirements

208 volt, 60 cycle, 3 phase power delivered through

5 wire cable (4 wire + ground.

Raised floor recommended with 5 inch clearance.

COST, PRICE AND RENTAL RATES

PURCHASE RENTAL

TYPICAL SYSTEM PRICE MONTH

Central Processor w/2,048 word/mem. $ 218,925 $ 4,865

4 Magnetic Tape Units 81,000 1,130

High Speed Printer 47,250 1,050

Card Reader-Punch 30,215 550

TOTAL $ 377,390 $ 8,265

ADDITIONAL EQUIPMENT

Additional Memory Blocks 1,024 words $ 29,250 $ 650

Multiply-Divide Option 11,250 250

Print-Storage Option 17,550 390

Rental price includes maintenance. Maintenance contract available for

purchased systems. Rates depend on age

of component, generally following decreasing scale.

PERSONNEL REQUIREMENTS

Varies with size of installation and applications.

Training made available by the manufacturer to the

user includes courses for executives, supervisors,

programmers and operators available to customers without cost.

RELIABILITY, OPERATING EXPERIENCE

Extensive built-in checking and special construction

techniques result in high reliability factor. System is modular

in construction designed for simplicity of maintenance

and replacement of parts.

ADDITIONAL FEATURES AND REMARKS

Outstanding features include unprogrammed transfers

automatically detect error conditions, orthotronic control

allows detection and correction of tape read errors,

program interrupt and priority processing are standard

features, adaptable to both scientific computation and

business data processing, large expansion possible and it

is compatible with Honeywell 1400.

The Honeywell 1400 is identical to the Honeywell 400

except that it is faster internally, and has a larger

expansion potential. Peripheral components in the

two systems are the same. Honeywell 400 users may switch

to the Honeywell 1400 without reprogramming.

PRODUCTION RECORD

First deliveries December 1963.

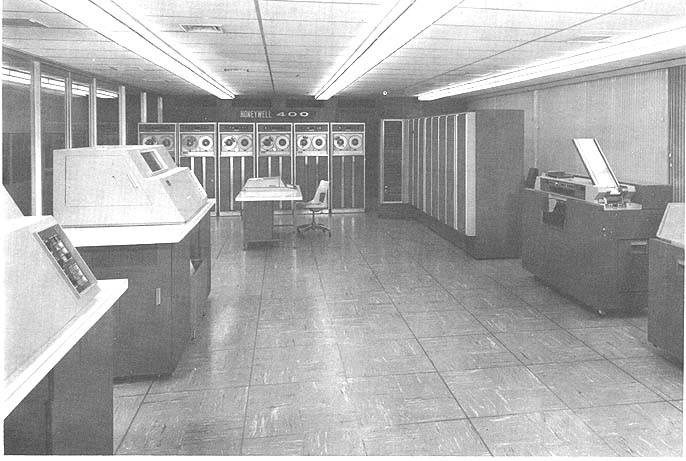

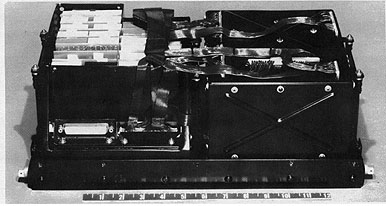

| BRL 1964, HONEYWELL 1400, starting page 0118

|

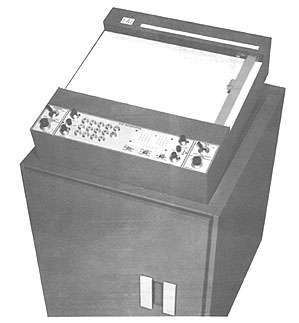

HONEYWELL 1400

MANUFACTURER

Minneapolis-Honeywell Regulator Company

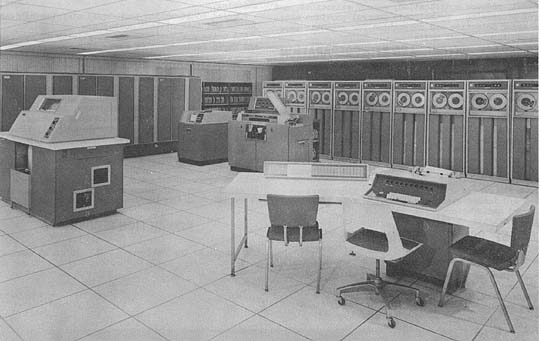

Photo by Minneapolis-Honeywell

APPLICATIONS

General purpose scientific and engineering computing. General purpose

business data processing. Real-time applications.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 + 2 check bits

Decimal digits/word 12 + 2 check bits

or 11 + sign + 2 check bits

Alphanumeric chars/word 8 + 2 check bits

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 73

Arithmetic system Fixed and floating point

Floating point is standard by sub-routine; optional by built-in hardware.

Fixed point is standard

Instruction type Three address

Number range

48 binary digits, 12 decimal digits, 11 decimal digits + sign

Floating point range 1051 to 10-49

Instruction word format

+---------+---------+-----------+-----------+

| 1 12 | 13 25 | 26 38 | 39 48 |

+---------+---------+-----------+-----------+

| Command | Address | B Address | C Address |

| Code | | | |

+---------+---------+-----------+-----------+

The command includes 6-bit operation code and 6-bit index register

designation.

Automatic built-in subroutines

Automatic subsequence on error conditions.

Extensive editing instructions.

Automatic coding

EASY-Assembly System

COBOL-Business Compiler

AUTOMATH-Scientific Compiler (FORTRAN II compatible)

Sort-Collate Routines

Scientific Library

Input/Output Package and Report Editor

PERT

Run Monitor

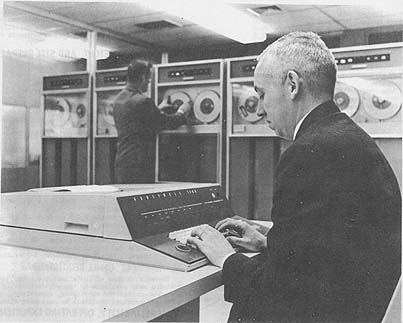

Photo by Minneapolis-Honeywell

APPLICATIONS

General purpose scientific and engineering computing. General purpose

business data processing. Real-time applications.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 + 2 check bits

Decimal digits/word 12 + 2 check bits

or 11 + sign + 2 check bits

Alphanumeric chars/word 8 + 2 check bits

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 73

Arithmetic system Fixed and floating point

Floating point is standard by sub-routine; optional by built-in hardware.

Fixed point is standard

Instruction type Three address

Number range

48 binary digits, 12 decimal digits, 11 decimal digits + sign

Floating point range 1051 to 10-49

Instruction word format

+---------+---------+-----------+-----------+

| 1 12 | 13 25 | 26 38 | 39 48 |

+---------+---------+-----------+-----------+

| Command | Address | B Address | C Address |

| Code | | | |

+---------+---------+-----------+-----------+

The command includes 6-bit operation code and 6-bit index register

designation.

Automatic built-in subroutines

Automatic subsequence on error conditions.

Extensive editing instructions.

Automatic coding

EASY-Assembly System

COBOL-Business Compiler

AUTOMATH-Scientific Compiler (FORTRAN II compatible)

Sort-Collate Routines

Scientific Library

Input/Output Package and Report Editor

PERT

Run Monitor

| BRL 1964, HONEYWELL 1400, starting page 0119

|

Registers and B-Boxes

Three Index Registers are standard.

ARITHMETIC UNIT

Average Time Incl.

Stor. Access Microsec

Fixed Floating

Decimal Add 78.0 149.5

Decimal Multiply 1,118.0 1,085.5

Decimal Divide 3,386.5 2,801.5

Binary Add 71.5 - -

The above times are for the three-address operation

A + B -> C etc. (11 decimal digits, operands + sign)

Arithmetic mode Parallel

Timing Asynchronous

Operation Sequential

Tape read-write overlap.

Card reader-punch, and printer buffers available.

Print-run can be performed simultaneously with another

program without special programming.

Simultaneous processing and program interrupt facilitate

real-time operation.

STORAGE

No. of No. of Access

Medium Words Digits Microsec

Magnetic Core 2,048 24,570 6.5

to 32,768 to 393,216

Magnetic Disk (max) 600,000,000 1,180 (Avg)

Magnetic Tape

No. of units that can be connected 16 Units

No. of digits/linear inch 1,110 Digits/inch

Channels or tracks on the tape 10 Track/tape

Blank tape separating each record 0.66 Inches

Tape speed 120 Inches/sec

Transfer rate decimal digits/sec 133,000 Digits/sec

Cross gap time 5.55 Millisec

Average time for experienced

operator to change reel of tape 20 Seconds

Physical properties of tape

Width 0.75 Inches

Length of reel 2,500 Feet

Composition

Mylar base with oxide coating.

Vacuum techniques used to mount reel, drive, stop and control tape.

Error detection and correction by orthotronic control.

Variable length records.

Other tape units operating at 48,000 and 96,000 decimal digits/second are

available.

INPUT

Medium Speed Remarks

Card Reader 800 cards/min (Card buffer avail)

Paper Tape Reader 500 or (5,6,7 or 8 channel

1,000 frames/sec

Ortho-scanner 1,500 doc/min

The scanner reads Honeywell ortho-bar code, rejection

rate is less than 0.1°%.

Optical-scanner 196, 240 or 312 doc/min Real-Time Input

Varies with circuit facilities on toll or leased wire circuits.

OUTPUT

Medium Speed

Card Punch 250 cards/min

Printer 900 lines/min

Paper Tape 110 frames/sec

Real-Time Output

Varies with circuit facilities on toll or leased wire circuits.

Buffered console keyboard and printer are standard.

Simultaneous peripheral processing. Program interrupt and

priority processing.

CHECKING FEATURES

Fixed:

Memory Parity (2 parity bits/word)

Internal Logic

Card Reader hole-count and data validity.

Card Punch hole-count and data validity.

Printer echo-check and data validity.

Magnetic Tape and disk orthotronic detection

and correction.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 42.0 KVA

Area, computer 745 sq ft

Floor loading 75 lbs/sq ft

Capacity, air conditioning 8 Tons

Site preparation requirements

208 volt, 60 cycle, 3 phase power delivered through

5 wire cable (4 wire + ground).

Raised floor recommended with 5 inch clearance.

COST, PRICE AND RENTAL RATES

TYPICAL SYSTEM PURCHASE MON/RENTAL

Central Processor w/4,096 word/mem. $ 330,750 $ 7,350

6 Magnetic Tape Units 121,500 2,700

High Speed Printer 47,250 1,050

Card Reader-Punch 30,215 550

TOTAL $ 529,715 $11,650

ADDITIONAL EQUIPMENT

Additional Memory Blocks 4,096 words $ 72,000 $ 1,600

Card Storage Option 22,050 490

Print Storage Option 17,550 390

Multi-Channel Communic. control 42,300 940

Floating Point Option 6,750 150

Multiply-Divide Option 11,250 250

Rental price includes maintenance. Maintenance contract available

for purchased systems. Rates depend on age of component, generally

following decreasing scale.

PERSONNEL REQUIREMENTS

Varies with size of installation and applications. Training

made available by the manufacturer to the user includes

courses for executives, supervisors, programmers and operators

available to customers without cost.

RELIABILITY, OPERATING EXPERIENCE

Extensive built-in checking and special construction techniques

result in high reliability factor. System is modular

in construction designed for simplicity of maintenance and

replacement of parts.

ADDITIONAL FEATURES AND REMARKS

Outstanding features include unprogrammed transfers automatically

detect error conditions, orthotronic control

allows detection and correction of tape read errors, program

interrupt and priority processing are standard

features, adaptable to both scientific computation and

business data processing, large expansion possible and it

is compatible with Honeywell 400.

The Honeywell 1400 is identical to the Honeywell 400

except that it is faster internally, and has a larger

expansion potential. Peripheral components in the two

systems are the same.

Honeywell 400 users many switch to the Honeywell 1400

without reprogramming.

PRODUCTION RECORD

First deliveries December 1963.

| BRL 1964, HONEYWELL 1800, starting page 0120

|

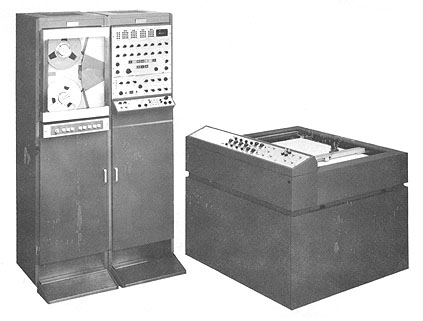

HONEYWELL 1800

MANUFACTURER

Minneapolis-Honeywell Regulator Co., EDP Div.

APPLICATIONS

General purpose scientific and engineering, (including

real-time), and general purpose business applications.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 (+ 6 check digits)

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 63 basic types

Arithmetic system Fixed & floating point

Floating point is standard by library routine and

optional by automatic floating-point unit.

Instruction type Three address

Number Range

Decimal: 10-65 up to 1063

Binary: 10-78 up to 1077

Instruction word format

+---------+-----------+-----------+-----------+

| 1 12 | 13 24 | 25 36 | 37 48 |

+---------+-----------+-----------+-----------+

| Command | A Address | B Address | C Address |

| Code* | | | |

+---------+-----------+-----------+-----------+

* Variously interpreted depending on instruction type.

Automatic built-in subroutines

Read/Write Error

Begin/End Tape

Parity Failure

Exponential Overflow/Underflow

Addition/Subtraction Overflow

Division Overcapacity

Automatic coding

Automatic routine generating and updating system.

Fully automatic compiling technique (FACT).

Automath(FORTRAN-IV compatible).

Common business oriented language (COBOL).

Computer organization package (COP) - includes

executive routine,

comprehensive file of systems programs,

sorts, library of subroutines and macroroutines.

Registers and B-Boxes

Eight groups of 32 registers each--total of 256

special registers. Each group has 2 arithmetic control

registers, 4 sequence/history registers, 1 unprogrammed

transfer register, 1 mask index register, 8 index registers,

4 input-output/general purpose registers,

and 12 general purpose registers.

There are also an accumulator and low-order product register;

a floating accumulator and floating loworder

product register, a floating auxiliary register; a mask register;

a program control register, and a machine control register.

ARITHMETIC UNIT

(Includes scientific option 1801-B)

Incl. Stor. Access

Microsec

Add 8

Mult 12

Div 22

Above times are for floating point operations.

Vacuum-Tubes 0

Transistors 3,000

Diodes 15,000 Arithmetic mode

Parallel - Serial - Parallel

Timing Synchronous

Operation Concurrent

Automatic parallel processing is entirely controlled by

two interrelated logical elements which allow up to eight

independent programs to proceed simultaneously:

1. Traffic Control directs the time sharing of main memory

cycles by sixteen input/output trunks and the central processor;

2. Multiprogram Control directs the time sharing of the central

processor by eight independent program control centers.

STORAGE

No. of Access

Medium Words Digits Microsec

Magnetic Core 32,768 393,216 2

(Main Memory)

Magnetic Core 256 1,024 2

(Control Memory)

Magnetic Disk 5,625,000 67,500,000 129,000

The magnetic core time given above is actually the cycle time,

and includes access and regeneration time.

Magnetic Tape

No. of units that can be connected 64 Units

No. of chars/linear inch 1,554 Chars/inch

Channels or tracks on the tape 10 Track/tape

Blank tape separating each record 0.67 Inches

Tape speed 120 Inches/sec

Transfer rate 133,000 or 186,000 Dec. dig/sec

Start time 3.5 Millisec

Stop time 3.5 Millisec

Average time for experienced

operator to change reel of tape 20 Seconds

Physical properties of tape

Width 0.75 Inches

Length of reel 2,500 Feet + 50 ft

Composition Mylar base with oxide coating

Magnetic tape with a transfer rate of 133,000 dec chars/second

is also available.

A vacuum is used to seat reels on hubs, to maintain loops

in loop chambers, and to provide contact with capstans.

INPUT

Medium Speed

Punched Card 240 cards/min

Punched Card 650 cards/min

Punched Card 800 cards/min

Paper Tape 500/1,000 frames/sec

Optical Scanning 312 doc/min

Magnetic Ink 1,160 doc/min

Magnetic Disk 1,160 doc/min

The communications control unit allows receipt and

transmission of data over toll or leased-wire circuits.

For real-time operations, control units and interfaces are supplied.

OUTPUT

Medium Speed

Printer 150/900 lines/min

Punched Card 100/250 cards/min

Paper Tape 110 frames/sec

Magnetic Disk

| BRL 1964, HONEYWELL 1800, starting page 0121

|

CIRCUIT ELEMENTS OF ENTIRE SYSTEM

Type Quantity Remarks

Tubes 0

Diodes 60,000 Excl. peripheral equipment

Transistors 12,000 Excl. peripheral equipment

CHECKING FEATURES

Accuracy assured through extensive internal checking,

verification of all data transmission, arithmetic processes,

address modification, memory selections, and control processing.

Orthotronic Control provides automatic error detection and

correction for magnetic tape and other input/output media.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 35 Kw 65 KVA 0.80 pf

(Typical system)

Air conditioner (Customer-supplied).

Area, data processing 1,580 sq ft

Area, service eng. 300 sq ft

Floor loading 75 lbs/sq ft

Capacity, air conditioner 13 Tons

Weight, computer 15,720 lbs

Site preparation requirements

Usual power requirements are for a source supplying

208 volts, 60-cycle, 3-phase, 4-wire, plus equipment ground.

Raised floors are used: A step-high floor with at least 5 1/2 inches

clearance above the true floor has been found satisfactory.

Ceiling height: 8 feet.

COST, PRICE AND RENTAL RATES

MONTHLY PURCHASE

D E S C R I P T I 0 N RENTAL PRICE

Central Processor (8,000 memory) $ 32,950 $1,585,200

Tape Control & 8 Units Card Reader/Punch Hi-Speed

Printer ) & Control

Additional Equipment:

1 Additional. memory block (8,000) 3,200 153,600

Floating Point Option 4,300 206,400

Training made available by the manufacturer to the user

includes training programs for executives, supervisors,

programmers and operators - without charge and tailored

to the needs of the user.

RELIABILITY, OPERATING EXPERIENCE

Each unit of entire system incorporates fail-safe checking.

Special construction techniques minimize cold-solder joints and

intermittent contacts.

All units are designed for simplicity of maintenance

and rapid replacement of parts.

ADDITIONAL FEATURES AND REMARKS

Outstanding features include high speed and flexibility.

Easily adapted to business or scientific problems - or to a

wide variety of special purpose activity (e.g., real-time, military,

information retrieval). Powerful proven software package.

Parallel processing, orthotronic control, floating point,

and nanosecond speed.

The system is compatible with Honeywell 800. There is a

wide choice of input/output equipment.

Relative humidity in the computer area should be held at

approximately 40°% to insure optimum tape performance.

Dry bulb temperature should not exceed 74oF;

wet bulb temperature should not exceed 59oF.

PRODUCTION RECORD

Time required for delivery 12 to 15 months

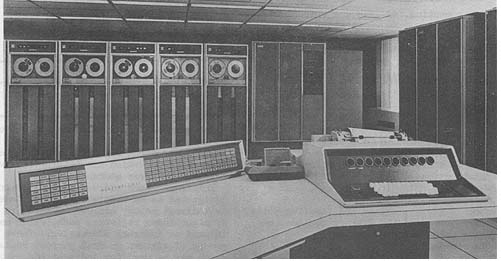

Photo by Minneapolis-Honeywell

Photo by Minneapolis-Honeywell

| BRL 1964, HONEYWELL 1800-II, starting page 0122

|

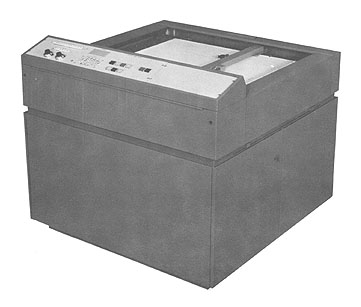

HONEYWELL 1800 II

MANUFACTURER

Minneapolis-Honeywell Regulator Company

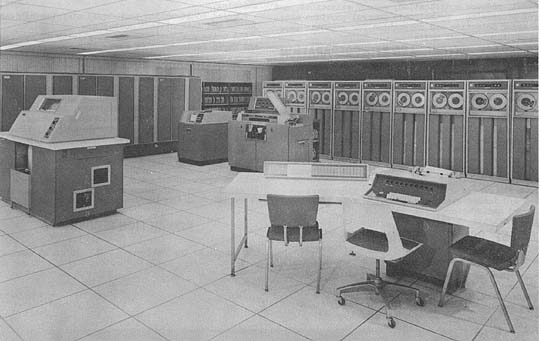

Photo by Minneapolis-Honeywell

APPLICATIONS

General purpose computing, on-line and real-time uses.

General purpose scientific and engineering computing.

General purpose business data processing and control

of real-time physical systems.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 (+ 6 check digits)

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 63 basic types

Arithmetic system Fixed & floating point

Floating point is standard by library routine and

optional by automatic floating-point unit.

Instruction type Three address

Number Range

Decimal: 10-65 up to 1063

Binary: 10-78 up to 1077

Instruction word format

+---------+-----------+-----------+-----------+

| 1 12 | 13 24 | 25 36 | 37 48 |

+---------+-----------+-----------+-----------+

| Command | A Address | B Address | C Address |

| Code | | | |

+---------+-----------+-----------+-----------+

The command code interpretation varies, depending on instruction type.

The instruction word is divided logically into four sections,

which are interpreted as a command code followed by three addresses.

Indexing. Each address in an instruction may be designated as an absolute

address, indexed address, or indirect memory address. There are

eight groups of eight index registers each, which may be used for

indexed or indirect addressing. There are also eight groups of

sixteen general purpose registers each, which may be used for indirect

addressing. An increment, which is automatically added to these registers,

can be indicated in an instruction.

Photo by Minneapolis-Honeywell

APPLICATIONS

General purpose computing, on-line and real-time uses.

General purpose scientific and engineering computing.

General purpose business data processing and control

of real-time physical systems.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary coded decimal

Binary digits/word 48 (+ 6 check digits)

Binary digits/instruction 48

Instructions/word 1

Instructions decoded 63 basic types

Arithmetic system Fixed & floating point

Floating point is standard by library routine and

optional by automatic floating-point unit.

Instruction type Three address

Number Range

Decimal: 10-65 up to 1063

Binary: 10-78 up to 1077

Instruction word format

+---------+-----------+-----------+-----------+

| 1 12 | 13 24 | 25 36 | 37 48 |

+---------+-----------+-----------+-----------+

| Command | A Address | B Address | C Address |

| Code | | | |

+---------+-----------+-----------+-----------+

The command code interpretation varies, depending on instruction type.

The instruction word is divided logically into four sections,

which are interpreted as a command code followed by three addresses.

Indexing. Each address in an instruction may be designated as an absolute

address, indexed address, or indirect memory address. There are

eight groups of eight index registers each, which may be used for

indexed or indirect addressing. There are also eight groups of

sixteen general purpose registers each, which may be used for indirect

addressing. An increment, which is automatically added to these registers,

can be indicated in an instruction.

| BRL 1964, HONEYWELL 1800-II, starting page 0123

|

Masking. The ability to mask words allows most internal processing

instructions in the Honeywell 1800 Il to work with fields of

variable length. Each program may designate a group of up to

96 memory locations as masking registers. Such a designation

may be changed by the programmer at any point in his program.

Thus, an essentially unlimited number of masking registers is

at his disposal.

Automatic built-in subroutines

Read/Write Error Detection

Begin End Tape

Parity Failure

Exponential Overflow/Underflow

Addition/Subtraction Overflow

Division Overcapacity

Automatic subsequencing to specified memory location.

Automatic coding

ARGUS - Automatic Routine Generating and Updating System;

Assembly System

FACT -Fully Automatic Compiling Technique;

Business Compiler COBOL - Common Business Oriented Language;

Business Compiler

AUTOMATH - FORTRAN IV compatible;

Scientific Compiler

COP - Computer Optimization Package; includes

executive routine, sort-collate routines,

input/output routine, library of sub-routines

and macro-routines, program test system.

ADMIRAL - Dynamic multiprogram operating system.

Registers and B-Boxes

Eight groups of 32 registers each - total 256 special registers.

Each group includes two Arithmetic Control Counters,

Sequence Counter, Consequence Counter, Sequence History Register,

Consequence History Register, Unprogrammed Transfer Register,

Mask Index Register, eight Index Registers and sixteen General Purpose

Registers.

The H-1800 and H-1800 II also includes: Accumulator and low-order product

register; floating accumulator and floating low-order product register;

floating auxiliary register; mask register, program control register,

machine control register.

ARITHMETIC UNIT

Average Time Incl.

Stor. Access

Microsec

Fixed Decimal Add 8

Fixed Decimal Multiply 54

Fixed Decimal Divide 44

Floating Binary Add 10

Floating Binary Multiply 10

Floating Binary Divide 28

The above times (include scientific floating point 1801B) are for the

three-address operation A + B - C etc. (11 decimal digits, operands + sign)

Construction (Arithmetic unit only)

Vacuum Tubes 0

Transistors 3,000

Diodes 15,000

Arithmetic mode Parallel-Serial-Parallel

Timing Synchronous Operation

Automatic parallel processing allows eight independent programs

to proceed simultaneously. This feature is hardware controlled and

requires no special programming or master monitor routine.

Traffic Control directs the time sharing of main memory cycles by 16

input/output trunks and the central processor.

Multiprogram Control directs the time sharing of the central processor by 8

independent program control centers.

The H-1800 and H-1800-II, are identical except that the H-1800-II includes

an Input/Output Control Center. This IOCC requires one input and an output

trunk and is capable of controlling one card reader, one card punch, one

high-speed printer and four magnetic tape units. All of these peripheral

units may be operated simultaneously, either on-line with the central

processor or off-line, in any combination of operations. Any combination

of peripheral units and their control units may be connected to the

remaining trunks.

Complete buffering allows Read/Write/Compute overlap.

STORAGE

No. of No. of Access

Medium Words Digits Microsec

Magnetic Core (Main) 65,536(Max)786,432 2

Access time includes access and restoration.

Magnetic Core (Control) 256 (16-bits) 1,024 2

Access time includes access and restoration. Magnetic Disk 100, 663, 000

(Max) 1,207,957,000(Max)

*129,000 (Avg) microseconds

Magnetic Tape

No. of units that can be connected 64 Units

No. of decimal digits/linear inch 1,550 Dig/inch

Channels or tracks on the tape 10 Track/tape

Blank tape separating each record 0.67 Inches

Tape speed 120 Inches/sec

Transfer rate decimal digits 186,000 Dig/sec

Start time 2.7 Millisec

Stop time 3.5 Millisec

Average time for experienced

operator to change reel of tape 20 Seconds

Physical properties of tape

Width 0.75 Inch

Length of reel 2,500 Feet

Composition

Mylar base with oxide coating.

Other magnetic tape units available with transfer rates of 48,000; 96,000;

133,000 decimal digits/sec.

Vacuum control used to seat reels on hubs to maintain loops in chambers,

and to provide contact with capstans.

Rewind speed 360 inches/second.

INPUT

Medium Speed Card Reader

Punched Card 240 cards/min Standard Speed

650 cards/min High Speed

800 cards/min Punch

Paper Tape 500 frames/sec (5,6,7, or 8 level codes)

1,000 frames/sec

Optical Scanning 312 doc/min (Max)

Magnetic Ink 1,160 doc/min (Max)

OUTPUT

Medium Speed Remarks

Printer 150 lines/min 120 position

900 lines/min 120160 position

Punched Card 100 cards/min Standard Speed Punch

250 cards/min Card Reader/Punch

Paper Tapes 110 frames/sec

Communications Control Unit allows H-1800-II to receive and transmit data

over toll or leased wire circuits.

For real-time operations, real-time control units and interfaces are

supplied.

| BRL 1964, HONEYWELL 1800-II, starting page 0124

|

CHECKING FEATURES

Accuracy assured through extensive checking of all internal and peripheral

operation; verification of all data

transfers, arithmetic operations; address modifications, memory selections

and control processing. Orthotronic

control provides detection and correction of tape read errors.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer typical system 71.7 KVA 80,% pf

Area, data processing 1,580 sq ft

Area, service engineer 300 sq ft

Floor loading 75 lbs/sq ft

Capacity, air conditioner 13 Tons

Weight, computer 15,720 lbs

Site preparation requirements

Power source supplying 208 volts, 60 cycle, 3 phase, 4-wire plus equipment

ground.

Air conditioner supplied by customer.

Raised floor with at least 5.5 inch clearance is recommended.

Ceiling height: 8 feet

Relative humidity in area should be held at approximately 45 /o to insure

optimum tape performance. Dry bulb-

wet bulb temperature should not exceed 74oF-59 F.

PRODUCTION RECORD

Time required for delivery 12 months

PERSONNEL REQUIREMENTS

Typical personnel requirement varies widely depending upon size of

installation and applications.

Training made available by the manufacturer to the user includes complete

executive, supervisor, programming,

operating courses at no cost to the customer.

RELIABILITY, OPERATING EXPERIENCE

Each unit of entire system incorporates fail-safe checking, special

construction, techniques eliminate cold-solder

joints and intermittent contacts. All units are modular in construction,

designed for simplicity of maintenance and

rapid replacement of parts.

ADDITIONAL FEATURES AND REMARKS

Exceptional speed and flexibility. Equally efficient with scientific or

business applications. Ability to run 8

programs in parallel and control a large number of peripheral, real time,

and communications devices add to its

flexibility. Extensive checking including orthotronic control for

correction of tape errors are standard features.

Unique system advantages include compatibility with Honeywell 800, and a

wide variety of peripheral devices

and parallel processing.

COST, PRICE AND RENTAL RATES

TYPICAL SYSTEM DESCRIPTION PURCHASE MONTHLY

PRICE RENTAL

Central Processor with 8,192 word memory $ 858,000 $ 18,000

Tape Control Unit 96,000 2,000

8 Magnetic Tape Units (96,000 cycles/sec) 345,600 7,200

High-Speed Printer 74,400 1,550

Card Reader-Punch 30,000 550

--------- -------

$1,404,000 $ 29,300

ADDITIONAL EQUIPMENT

Floating Point Option $ 206,400 $ 4,300

Additional Memory Blocks (8,192 words) 153,600 3,200

| BRL 1964, HONEYWELL 1800-II, starting page 0125

|

| BRL 1964, HUGHES HCM 101, starting page 0126

|

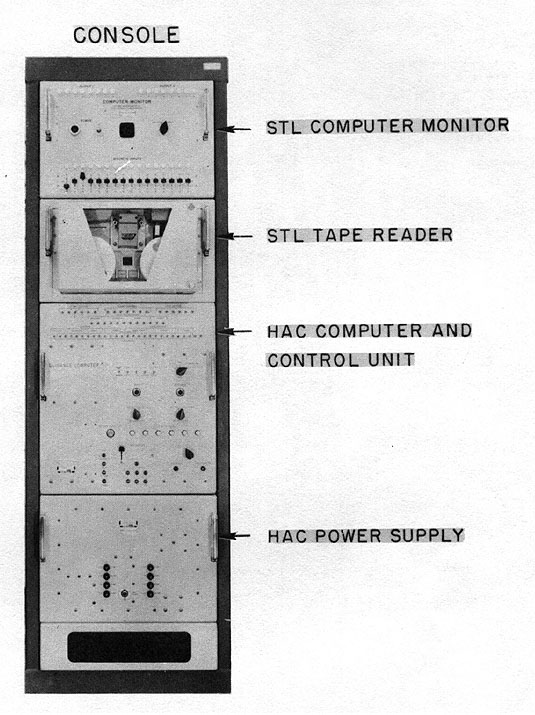

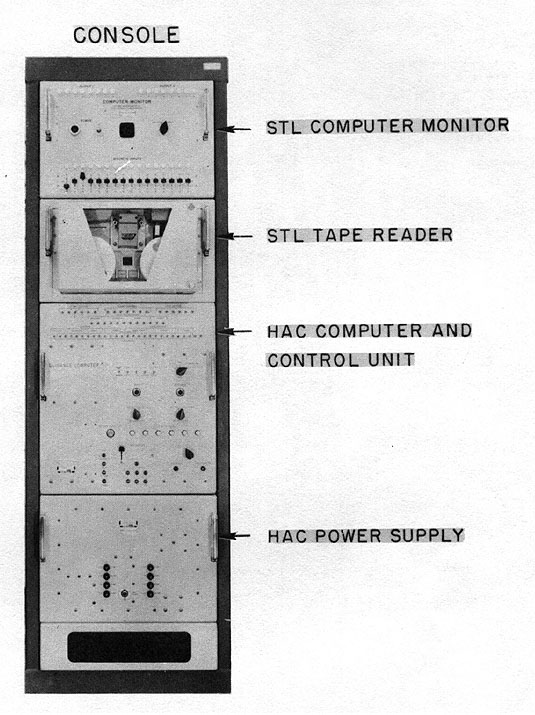

HUGHES HCM 101

MANUFACTURER

Hughes Aircraft Company

APPLICATIONS

Aircraft fire control, navigation, system test, etc. The system is based on

the LRI-X System, and was developed for the AN/ASG-18 Fire Control System.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 21

Binary digits/instruction 21

Instructions/word 1

Arithmetic system Fixed point

Instruction type One address

Number range +- 218

Instruction word format Variable

Automatic coding

An assembler has been prepared. Registers and B-Boxes

There are 16 fast-access (4 word) registers.

Variable length multiply and divide features are available.

ARITHMETIC UNIT

Excl. Stor. Access

Microsec

Add 80

Mult 40/bit

Div 40/bit

Construction (Arithmetic unit only) Silicon transistors are used.

Arithmetic mode Serial

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary Access

Medium Words Digits/Word Microsec

Magnetic Drum 62,000 21 12,500(avg)

INPUT

No. of Lines

Medium Available

AC Analog Lines 24

DC Analog Lines 40

Incremental Lines 4

Digital Lines 120

OUTPUT

No. of Lines

Medium Available

DC Lines 32

Servo Lines 20

Incremental Lines 3

Digital Lines 6

CIRCUIT ELEMENTS OF ENTIRE SYSTEM

All silicon semiconductors are used.

CHECKING FEATURES

A built-in automatic self-test routine is run, with fault isolation to

identify a faulty circuit card.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 0.57 Kw

Volume, computer 4 cu ft

Weight, computer 164 lbs

| BRL 1964, HUGHES HCM 121, starting page 0127

|

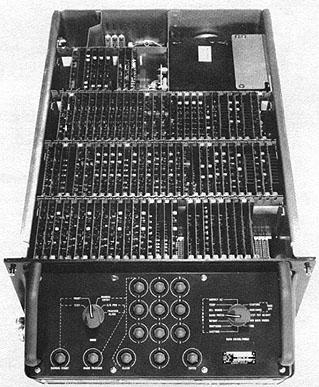

HUGHES HCM 121

Command Guidance Computer

MANUFACTURER

Hughes Aircraft Company

Photo by Hughes Aircraft Company

APPLICATIONS

Space probe guidance and control. The system is used in connection with

the Atlantic Missile Range.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 26

Binary digits/instruction 13

Instructions/word 2

Arithmetic system Floating point

Instruction type One address

Number range +- 223

Instruction word format Variable

ARITHMETIC UNIT

Excl. Stor. Access Microsec

Add 95

Mult 48

Div 48

Operation times are per bit.

Construction (Arithmetic unit only)

Transistors

Arithmetic mode Serial

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary Access

Medium Words Digits/Word Microsec

Drum 5,280 13 5,700

INPUT AND OUTPUT

Digital for both.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 0.170 Kw

Volume, computer 2.3 cu ft

Weight, computer 85 lbs

PRODUCTION RECORD

Number produced to date 14

Time required for delivery 8 months

Photo by Hughes Aircraft Company

APPLICATIONS

Space probe guidance and control. The system is used in connection with

the Atlantic Missile Range.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 26

Binary digits/instruction 13

Instructions/word 2

Arithmetic system Floating point

Instruction type One address

Number range +- 223

Instruction word format Variable

ARITHMETIC UNIT

Excl. Stor. Access Microsec

Add 95

Mult 48

Div 48

Operation times are per bit.

Construction (Arithmetic unit only)

Transistors

Arithmetic mode Serial

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary Access

Medium Words Digits/Word Microsec

Drum 5,280 13 5,700

INPUT AND OUTPUT

Digital for both.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 0.170 Kw

Volume, computer 2.3 cu ft

Weight, computer 85 lbs

PRODUCTION RECORD

Number produced to date 14

Time required for delivery 8 months

| BRL 1964, HUGHES HCM 122, starting page 0128

|

HUGHES HCM 122

Surveillance Data Analyzer

MANUFACTURER

Hughes Aircraft Company

Photo by the Hughes Aircraft Company

APPLICATIONS

The AN/UVS-l Target Locating System for use with the unmanned drone.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 26

Binary digits/instruction 13

Instructions/word 2

Arithmetic system Fixed point

Instruction type One address

Number range +- 223

Instruction word format Variable

ARITHMETIC UNIT

Excl. Stor. Access

Microsec

Add 88

Mult 44/bit

Div 44/bit

Construction (Arithmetic unit only)

Transistors

Arithmetic mode Serial

Timing Synchronous

Operation Sequential

STORAGE

No. of Binary Access

No. of Digits/Word Microsec

Drum 5,760 26 5,700

INPUT AND OUTPUT

Analog and Digital

POWER, SPACE, WEIGHT, AND SITE. PREPARATION

Power, computer 0.17 Kw

Volume, computer 2.3 cu ft

Weight, computer 85 lbs

PRODUCTION RECORD

Number produced to date 4

Time required for delivery 9 months

Photo by the Hughes Aircraft Company

APPLICATIONS

The AN/UVS-l Target Locating System for use with the unmanned drone.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 26

Binary digits/instruction 13

Instructions/word 2

Arithmetic system Fixed point

Instruction type One address

Number range +- 223

Instruction word format Variable

ARITHMETIC UNIT

Excl. Stor. Access

Microsec

Add 88

Mult 44/bit

Div 44/bit

Construction (Arithmetic unit only)

Transistors

Arithmetic mode Serial

Timing Synchronous

Operation Sequential

STORAGE

No. of Binary Access

No. of Digits/Word Microsec

Drum 5,760 26 5,700

INPUT AND OUTPUT

Analog and Digital

POWER, SPACE, WEIGHT, AND SITE. PREPARATION

Power, computer 0.17 Kw

Volume, computer 2.3 cu ft

Weight, computer 85 lbs

PRODUCTION RECORD

Number produced to date 4

Time required for delivery 9 months

| BRL 1964, HUGHES HCM 301, starting page 0129

|

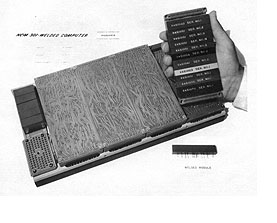

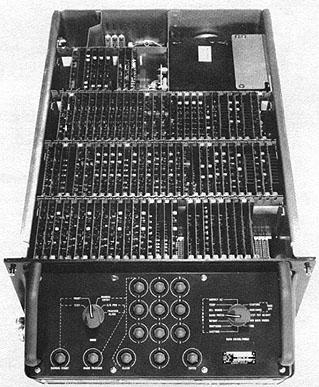

HUGHES HCM 301

MANUFACTURER

Hughes Aircraft Company

Photo by Hughes Aircraft Company

APPLICATIONS

The system is a digital differential analyzer used .

for ballistic missile guidance.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 17

Binary digits/instruction 17

Instructions/word 1

Arithmetic system Fixed point

Instruction type Sequential wired program.

Number range +- 216

ARITHMETIC UNIT

The arithmetic unit performs 800 iterations/second.

Construction (Arithmetic unit only)

The arithmetic unit consists of transistors,

diodes, and magnetic cores.

Arithmetic mode Series - parallel

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary

Medium Words Digits/Word

Magnetic Core Shift Register 11 17

Photo by Hughes Aircraft Company

APPLICATIONS

The system is a digital differential analyzer used .

for ballistic missile guidance.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 17

Binary digits/instruction 17

Instructions/word 1

Arithmetic system Fixed point

Instruction type Sequential wired program.

Number range +- 216

ARITHMETIC UNIT

The arithmetic unit performs 800 iterations/second.

Construction (Arithmetic unit only)

The arithmetic unit consists of transistors,

diodes, and magnetic cores.

Arithmetic mode Series - parallel

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary

Medium Words Digits/Word

Magnetic Core Shift Register 11 17

| BRL 1964, HUGHES HCM 201, starting page 0130

|

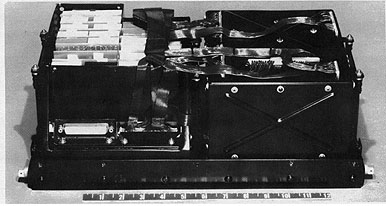

HUGHES HCM 201

MANUFACTURER

Hughes Aircraft Company

Photo by Hughes Aircraft Company

APPLICATIONS

Guidance and Control, navigation of Aerospace vehicles.

It is designed for operation in military

environments. It can be installed in missiles, satellites,

aircraft, ship or vans.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 24

Binary digits/instruction 12

Instructions/word 2

Instructions decoded 30

Instruction type One address

Instruction word format Variable

Depending on type of instruction.

Automatic coding

An assembler is being developed.

Registers and B-Boxes

8 Index Registers

ARITHMETIC UNIT

Incl. Stor. Access Excl. Stor. Access

Microsec Microsec

Add 6 6

Mult 120 120

Div 120 120

Construction (Arithmetic unit only)

Vacuum-Tubes 0

Transistors 829

Diodes 2,951

Magnetic Cores

Depends on size of memory.

Arithmetic mode Parallel

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary Access

Medium Words Digits/Word Microsec

Magnetic Core 16,000 24 6

(Transfluxor)

Magnetic Core 4,000 24 6

Magnetic Drum 1,500,000

(Gas Bearing)

Magnetic Tape

No. of units that can be connected 0 Units

INPUT

Medium Analog (AC & DC)

Digital

Discrete

Photo by Hughes Aircraft Company

APPLICATIONS

Guidance and Control, navigation of Aerospace vehicles.

It is designed for operation in military

environments. It can be installed in missiles, satellites,

aircraft, ship or vans.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 24

Binary digits/instruction 12

Instructions/word 2

Instructions decoded 30

Instruction type One address

Instruction word format Variable

Depending on type of instruction.

Automatic coding

An assembler is being developed.

Registers and B-Boxes

8 Index Registers

ARITHMETIC UNIT

Incl. Stor. Access Excl. Stor. Access

Microsec Microsec

Add 6 6

Mult 120 120

Div 120 120

Construction (Arithmetic unit only)

Vacuum-Tubes 0

Transistors 829

Diodes 2,951

Magnetic Cores

Depends on size of memory.

Arithmetic mode Parallel

Timing Synchronous

Operation Sequential

STORAGE

No. of No. of Binary Access

Medium Words Digits/Word Microsec

Magnetic Core 16,000 24 6

(Transfluxor)

Magnetic Core 4,000 24 6

Magnetic Drum 1,500,000

(Gas Bearing)

Magnetic Tape

No. of units that can be connected 0 Units

INPUT

Medium Analog (AC & DC)

Digital

Discrete

| BRL 1964, HUGHES HCM 201, starting page 0131

|

OUTPUT

Medium Analog (DC)

Digital

Servomechanism

CIRCUIT ELEMENTS OF ENTIRE SYSTEM

Type Quantity

Tubes 0

Diodes 7,000

Transistors 2,000

All silicon semiconductors are used.

CHECKING FEATURES

The system has a complete self-test capability

with fault isolation routines.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 0.150 Kw 28 Volt DC

Weight, computer 51 lbs

An air conditioner is not required.

PRODUCTION RECORD

Number produced to date 1

Number in current operation 1

Number in current production 10

Time required for delivery 6 months

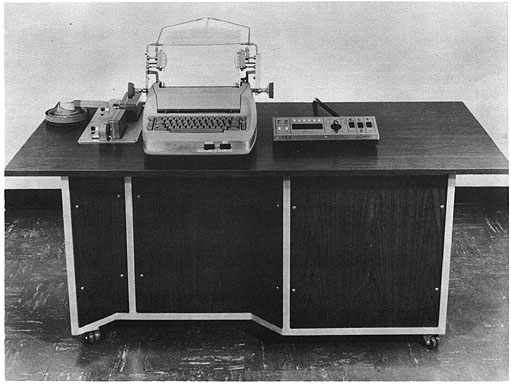

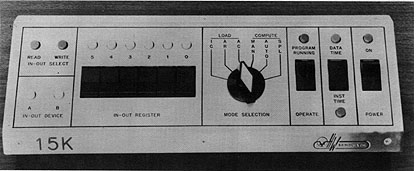

| BRL 1964, HUGHES HW 15K, starting page 0132

|

HW 15K

MANUFACTURER

H-W-Electronics, Inc.

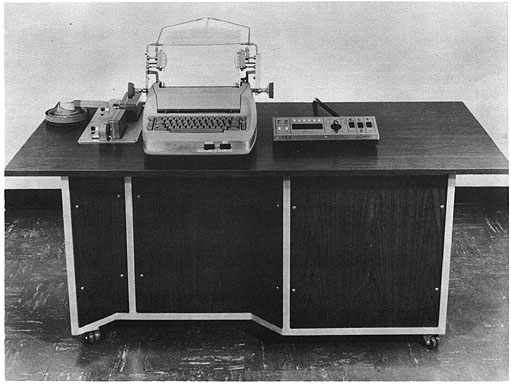

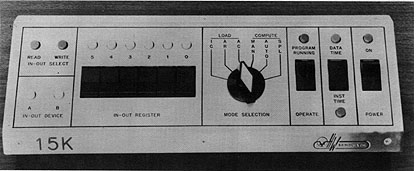

Photo by H-W-Electronics, Inc.

APPLICATIONS

Engineering office and small business office applications.

The computer may be adopted to any specific application

within the scope of the machine's capability.

For example, an on-line application where a customer his

several sets of input data which must be

scanned in sequence or in parallel and then operated upon.

This, of course will dictate additional buffer

registers which can then be used for other routines.

The IN-15K general purpose computer is a machine

capable of the payroll, inventory, and editing

function in a business application, and of the mathematical

routines of the engineering office. The HW-15K may also

serve as a rack-mounted version in special situations or

on-line applications in industry, or

as a satellite computer in a large computer installation.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 24

Instructions/word 1

Instructions decoded 12

Arithmetic system Fixed point

Instruction type One address

Number range +- (223- 1) or 8,388,607

Instruction word format

+-------+------+--------+---------+--------+

| 1 6 | 7 10 | 11 12 | 13 17 | 18 24 |

+-------+------+--------+---------+--------+

| Spare | OP | I/0 | Track | Word |

+-------+------+--------+---------+--------+

| | Code | | Address |

+-------+------+--------+------------------+

Address

Registers and B-Boxes

Accumulater Register (AC)

Instruction Counter (IC)

Action Register (AR)

ARITHMETIC UNIT

Incl. Stor. Access

Microsec

Add 650

Arithmetic mode Serial

The basic pulse repetition rate is 192,000 cycles/sec

Timing Synchronous

Operation Concurrent

Photo by H-W-Electronics, Inc.

APPLICATIONS

Engineering office and small business office applications.

The computer may be adopted to any specific application

within the scope of the machine's capability.

For example, an on-line application where a customer his

several sets of input data which must be

scanned in sequence or in parallel and then operated upon.

This, of course will dictate additional buffer

registers which can then be used for other routines.

The IN-15K general purpose computer is a machine

capable of the payroll, inventory, and editing

function in a business application, and of the mathematical

routines of the engineering office. The HW-15K may also

serve as a rack-mounted version in special situations or

on-line applications in industry, or

as a satellite computer in a large computer installation.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 24

Instructions/word 1

Instructions decoded 12

Arithmetic system Fixed point

Instruction type One address

Number range +- (223- 1) or 8,388,607

Instruction word format

+-------+------+--------+---------+--------+

| 1 6 | 7 10 | 11 12 | 13 17 | 18 24 |

+-------+------+--------+---------+--------+

| Spare | OP | I/0 | Track | Word |

+-------+------+--------+---------+--------+

| | Code | | Address |

+-------+------+--------+------------------+

Address

Registers and B-Boxes

Accumulater Register (AC)

Instruction Counter (IC)

Action Register (AR)

ARITHMETIC UNIT

Incl. Stor. Access

Microsec

Add 650

Arithmetic mode Serial

The basic pulse repetition rate is 192,000 cycles/sec

Timing Synchronous

Operation Concurrent

| BRL 1964, HUGHES HW 15K, starting page 0133

|

Photo by H-W-Electronics, Inc.

Processing concurrent with Input/output operations.

STORAGE

No. of No. of Bin.

Medium Words Digits/Word

Magnetic Drum 4,096 24

The drum rotates at 3,600 revolutions/minute. The

capacity may be increased.

INPUT

Medium Speed

Paper Tape 20 chars/sec

Keyboard (IBM Selectric) Manual

OUTPUT

Medium Speed

Paper Tape 20 chars/sec

Typewriter (IBM Selectric) 15 chars/sec

CIRCUIT ELEMENTS OF ENTIRE SYSTEM

Solid-state circuit elements are used; transistors,

crystal diodes, and printed circuits.

CHECKING FEATURES

Parity is checked when transferring out of storage.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 0.8 Kw 1.0 KVA

Volume, computer 64 in x 30 in.x 31 1/2 in.

Site preparation requirements

105 - 125 volts, 60 cycle/sec power.

Air conditioning is not required.

COST, PRICE AND RENTAL RATES

Computer, with 4,096-word magnetic drum, paper tape input-output,

and typewriter is less than $20,000.00.

ADDITIONAL FEATURES AND REMARKS

Constructed of standard tested and proved modules

manufactured by H-W-Electronics for many years. It

was a logical step to assemble these modules into

two 19-inch relay-rack assemblies, attach the storage

drum and input-output equipment, and fit the packages

into a desk.

OPERATION CODE,.

BINARY INSTRUCTION EFFECT

0000 - HLT Halt

0001 - NOP No Operation

0010 - TRA Transfer

0011 - TRN Transfer if AC negative

Ol00XX RDE Read

0101XX WTE Write

0110 - SHR Shift Right

0111 - CYR Cycle Right

1000 - CLA Clear and Add

1001 - spare

1010 - ADD Add

1011 - SUB Subtract

1100 - STO Store

1101 - spare

1110 - spare

1111 - spare

Photo by H-W-Electronics, Inc.

Processing concurrent with Input/output operations.

STORAGE

No. of No. of Bin.

Medium Words Digits/Word

Magnetic Drum 4,096 24

The drum rotates at 3,600 revolutions/minute. The

capacity may be increased.

INPUT

Medium Speed

Paper Tape 20 chars/sec

Keyboard (IBM Selectric) Manual

OUTPUT

Medium Speed

Paper Tape 20 chars/sec

Typewriter (IBM Selectric) 15 chars/sec

CIRCUIT ELEMENTS OF ENTIRE SYSTEM

Solid-state circuit elements are used; transistors,

crystal diodes, and printed circuits.

CHECKING FEATURES

Parity is checked when transferring out of storage.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 0.8 Kw 1.0 KVA

Volume, computer 64 in x 30 in.x 31 1/2 in.

Site preparation requirements

105 - 125 volts, 60 cycle/sec power.

Air conditioning is not required.

COST, PRICE AND RENTAL RATES

Computer, with 4,096-word magnetic drum, paper tape input-output,

and typewriter is less than $20,000.00.

ADDITIONAL FEATURES AND REMARKS

Constructed of standard tested and proved modules

manufactured by H-W-Electronics for many years. It

was a logical step to assemble these modules into

two 19-inch relay-rack assemblies, attach the storage

drum and input-output equipment, and fit the packages

into a desk.

OPERATION CODE,.

BINARY INSTRUCTION EFFECT

0000 - HLT Halt

0001 - NOP No Operation

0010 - TRA Transfer

0011 - TRN Transfer if AC negative

Ol00XX RDE Read

0101XX WTE Write

0110 - SHR Shift Right

0111 - CYR Cycle Right

1000 - CLA Clear and Add

1001 - spare

1010 - ADD Add

1011 - SUB Subtract

1100 - STO Store

1101 - spare

1110 - spare

1111 - spare

| BRL 1964, HYDAC 2000, starting page 0134

|

HYDAC 2000

Hybrid Digital Analog Computer

MANUFACTURER

Electronics Associates, Inc.

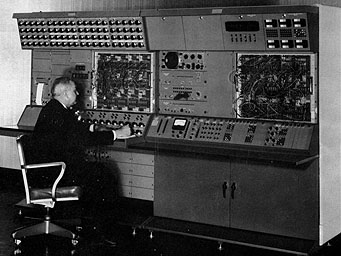

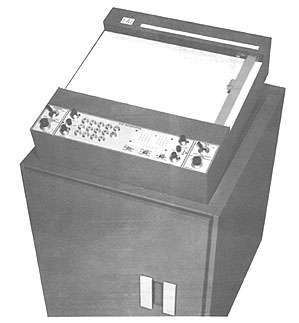

Photo by Electronics Associates, Inc.

APPLICATIONS

The HYDAC, Series 2000, is a general-purpose,

hybrid analog and digital computing system providing

automatic operation of the high-speed analog computing

capacility to permit iterative and sequential

computation for a broad class of problems in many

fields of engineering. The logic, memory, conversion

and input-output features extend the use of analog

computing techniques into new fields such as data

processing and statistical analysis. The digital system

is also very effective as a simulator of digital

controllers which may be used in conjunction with a

dynamic simulation of the physical system on the

analog console.

The HYDAC 2000 is composed of a general-purpose

analog computing console with a special control patch

panel and a digital console composed of logic elements,

memory units, analog-to-digital and digital-to-

analog converters, plus a paper tape input-output

system. To provide the parallel operation required for

compatibility with the analog computer, the digital

elements terminate on a removable patch-panel

similar to the analog console. This approach allows

multiple channels of logical control and memory to

communicate with the analog system simultaneously

at very high speed. Analog computer portion is

PACE 2318 V. Digital Operations System is DOS 350.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 16

Arithmetic system Fixed point

Multiple parallel, adding-subtracting units.

Photo by Electronics Associates, Inc.

APPLICATIONS

The HYDAC, Series 2000, is a general-purpose,

hybrid analog and digital computing system providing

automatic operation of the high-speed analog computing

capacility to permit iterative and sequential

computation for a broad class of problems in many

fields of engineering. The logic, memory, conversion

and input-output features extend the use of analog

computing techniques into new fields such as data

processing and statistical analysis. The digital system

is also very effective as a simulator of digital

controllers which may be used in conjunction with a

dynamic simulation of the physical system on the

analog console.

The HYDAC 2000 is composed of a general-purpose

analog computing console with a special control patch

panel and a digital console composed of logic elements,

memory units, analog-to-digital and digital-to-

analog converters, plus a paper tape input-output

system. To provide the parallel operation required for

compatibility with the analog computer, the digital

elements terminate on a removable patch-panel

similar to the analog console. This approach allows

multiple channels of logical control and memory to

communicate with the analog system simultaneously

at very high speed. Analog computer portion is

PACE 2318 V. Digital Operations System is DOS 350.

PROGRAMMING AND NUMERICAL SYSTEM

Internal number system Binary

Binary digits/word 16

Arithmetic system Fixed point

Multiple parallel, adding-subtracting units.

| BRL 1964, HYDAC 2000, starting page 0135

|

Automatic built-in subroutines.

A variety of subroutine programs have been written for

memory operations, and input-output. Routines

for performing various arithmetic operations such

as multiplication and resolution have also been

prepared. These sub-routines are patched on the

removable, storable panels of the digital console.

Although the HYDAC 2000 system is not designed to

provide conventional stored program capability,

arithmetic units are provided to supplement the

mathematical capability of the analog system. This

capability is used both in a time-shared fashion

to reduce the use of analog elements as well as

a convenient means of performing simple arithmetic

operations in conjunction with other digital

programs such as function generation.

ARITHMETIC UNIT

Excl. Stor. Access

Microsec

Add 8

Mult 128

Arithmetic mode Serial

Timing Synchronous

Operation Concurrent

STORAGE

No. of No. of Binary Access

Medium Words Digits/Word Microsec

Magnetostrictive 3,082 16 bits 8 sequential

Delay Lines 2 random

INPUT

Medium Speed

Paper Tape 500 - 1,000 chars/sec

Bi-directional reader with spooler for 500 chars second.

OUTPUT

Medium Speed

Paper Tape 110 chars/sec

Tape is spooled on compatible reels

CIRCUIT ELEMENTS OF ENTIRE SYSTEM

Type Quantity

Tubes

6072 200

6U8 125

6AW8 125

7719 250

----

Total 700

Diodes

ED1871A 12,000

CTP462 1,000

CR5488 1,600

ED6008 1,000

------

Total 15,600

Transistors

SM291 5,000

SM423 800

2N404 400

2N964 300

2N2276 150

2N797 100

2N1308 100

2N324 200

-----

Total 7,050

Magnetic Cores 0

Other diodes, transistors and tubes comprise

insignificant percentage of total.

CHECKING FEATURES

Neon indicators for all flip-flops with associated

Manual Set-Reset Control.

Logic and Signal Selector (Addressable selection of

all Logic or Analog Elements without Fixed-Readout

Voltage Monitor Panel (Meters all system voltages

Static Test. Rate Test and Initial Derivatives test

for analog components.

Amplifier Overload Indicator.

Reduced Clock and Manual Clock provisions for DOS 350.

POWER, SPACE, WEIGHT, AND SITE PREPARATION

Power, computer 8 KVA

Power, air conditioner 4 KVA

Volume, computer 300 cu ft

Area, computer 65 sq ft

Floor loading, computer 110 lbs/sq ft

Volume, air conditioner 35 cu ft

Area, air conditioner 10 sq ft

Capacity, air conditioner 5 Tons

Weight, computer 7,000 lbs

Weight, air conditioner 1,000 lbs

Site preparation requirements

Depends on site but usually only air conditioning

is necessary for the analog portion.

PERSONNEL REQUIREMENTS

One 8-Hour Two 8-Hour

Shift Shifts

Analysts 2 2

Programmers 2 3

Technicians 1 2

Training is made available by the manufacturer

to the user including a 1 week maintenance course,

a 1 week operator/programmer course, and an advanced

application course of 1 and 2 weeks.

RELIABILITY, OPERATING EXPERIENCE

I DOS 350 - Digital Operations System

Basic circuit units in the system are high quality,

ultra-reliable digital basic building blocks (potted,

welded modules. These modules are mounted on plugin,

etched circuit boards, which, in general, are

housed in plug-in, logic building blocks. For this

reason, with a minimum number of spares, faulty units

may be quickly replaced and repairs made as work

load permits, without incurring costly computer

down-time.

II PACE 2318 V - General Purpose Analog-Computer

Performance-proven design with basic concepts and

operating experience since 1953. Plug-in,

removable chassis concept produces same results

as cited above for DOS 350.

ADDITIONAL FEATURES AND REMARKS

Permits simulating complex, dynamic systems requiring

both analog facilities and digital logic and

memory in one, integrated system.

Series 3110-3120-3130 Dataplotter, 11" x 17" Digital

X-Y Plotter, Punched Card or Tape Input.

On-line capability: Research-engineering, statistics,

production, meteorogogical monitoring, telemetry,

and map making.

| BRL 1964, HYDAC 2000, starting page 0136

|

MODEL 3130 EAI DATAPLOTTER SPECIFICATIONS

Data Input

PUNCHED CARDS: Read with modified IBM 407, 513, 514, 517,

519, 523, 024, 026 and 526 Summary Punches. The standard

IBM Card of 80 columns and 12 rows is used.

PUNCHED PAPER TAPE: Read with a modified Friden,

Model 2, motorized tape reader. Accepts BCD code

in serial form on 5, 7 and 8 level tape.

KEYBOARD: Manually operated. Other inputs available on special order.

Data Output

POINT PLOT: Maximum useable plotting surface of

10" x 15". Scale factor and parallax controls allow the

plotting of a graph on any portion of the plotting surface.

CODED SYMBOLS: Semi-Automatic Symbol Printer available

as accessory. Up to 6 distinct symbols.

Plotting Speed

PUNCHED CARDS: Up to 100 points per minute.

PAPER TAPE: Up to 120 points per minute.

LINE: Up to 70 per minute.

Plotting Accuracy

VARIPLOTTER: Static Accuracy - 0.075% of full scale

for pen and arm.

CONVERSION: less than 0.1%.

Physical Description

Height 35 inches

Width . . 22 inches

Weight (Uncrated) 203 Ibs. (Punched Card Input)

Weight , . 225 Ibs. (Card and tape Input)

Depth 26 inches

Power 115 volts, 100 watts

Dataplotter 3110 Photo by Electronics Associates, Inc.

Dataplotter 3110 Photo by Electronics Associates, Inc.

| BRL 1964, HYDAC 2000, starting page 0137

|

Dataplotter 3120 Photo by Electronics Associates, Inc.

HYDAC 200 - Series 3440 Dataplotter, 30" x 30" Digital X-Y

Plotter, Magnetic Tape, Punched Card or Tape Input

Weather Charts

Mapping

Missile Tracking

Test Simulation

Statistics

Fully buffered.

Dataplotter series 3440 is designed to provide fast accurate

graphic recording of digital data from a variety of inputs.

Operates from magnetic tape, punched cards, papertape or keyboard.

Dataplotter 3120 Photo by Electronics Associates, Inc.

HYDAC 200 - Series 3440 Dataplotter, 30" x 30" Digital X-Y

Plotter, Magnetic Tape, Punched Card or Tape Input

Weather Charts

Mapping

Missile Tracking

Test Simulation

Statistics

Fully buffered.

Dataplotter series 3440 is designed to provide fast accurate

graphic recording of digital data from a variety of inputs.

Operates from magnetic tape, punched cards, papertape or keyboard.

| BRL 1964, HYDAC 2000, starting page 0138

|

Dataplotter 3440 Photo by Electronics Associates, Inc.

MODEL 3440 EAI DATAPLOTTER

DATA INPUT

Magnetic Tape: Accepts 1 inch wide, 7 track, BCD tape,

written at a density of 200 characters per inch.**

Punched Cards: Read with parallel or serial fed Card Readers.

Punched Tape: High speed photo-electric reader capable

of reading tape with up to 8 levels.

Keyboard: Manually operated-adding machine type.

DATA OUTPUT*

Point Plot: Any size paper up to 30 inch x 30 inch

(available in plain or ruled sheets or rolls)

Continuous Line: Any size reproducible ink drawing on

any size paper up to 30 inch x 30 inch.

Coded Plots: Symbols-up to 12 distinct symbols (average

selection time 0.33 seconds) ; Numeric point identification.

PLOTTING ACCURACY (quoted as maximum errors)

Analog Plotter: 0.015 inches

Data Conversion: within 4 counts

Line Segment Conformity: 0.015 inches

PHYSICAL DESCRIPTION

Tape Reader and

Console X-Y Plotter

Width (overall) 42" 46"

Depth (overall) 32" 46 1/2"

Height 75 1/4" 41 1/2"

Weight (uncrated) 1212 lbs. 660 lbs.

Power-Requires 30 amp, 115V, 60 cycle (single phase)

service. (50 cycle model available on special order)

PLOTTING SPEEDS

Point Plots: Magnetic Tape (at 1/8 inch spacing) at least

350 ppm

Punched Cards:

Serial-fed-nominally 75 ppm

Parallel-fed-nominally 100 ppm

Punched Tape- nominally 300 ppm

Line Plot: Magnetic Tape: (depends upon setting of

Max. Point Displacement switch)

1/8 inch-540 lines/min

1/4 inch-306 lines/min

1/2 inch-144 lines/min

1 inch-114 lines/min

2 inch- 90 lines /min

5 inch- 42 lines/min

Punched Cards

Serial-fed-maximum 75 lines/min

Parallel-fed-maximum 100 lines/min

Punched Tape

maximum 300 lines/min

Coded Plots (1/2 inch spacing):

Magnetic Tape-at least 180 ppm

Punched Cards

Serial-fed-75 ppm

Parallel-fed-100 ppm

Punched Tape-180 ppm

Free Running Mode-up to 4500 ppm

(Data points are read at 75 inches per second

tape speed without stopping in the record gaps)

* Wide line (up to 1/16 inch) pens are available

** Other formats available on special order

(All equipment specifications contained herein are subject to change)

Dataplotter 3440 Photo by Electronics Associates, Inc.

MODEL 3440 EAI DATAPLOTTER

DATA INPUT

Magnetic Tape: Accepts 1 inch wide, 7 track, BCD tape,

written at a density of 200 characters per inch.**

Punched Cards: Read with parallel or serial fed Card Readers.

Punched Tape: High speed photo-electric reader capable

of reading tape with up to 8 levels.

Keyboard: Manually operated-adding machine type.

DATA OUTPUT*

Point Plot: Any size paper up to 30 inch x 30 inch

(available in plain or ruled sheets or rolls)

Continuous Line: Any size reproducible ink drawing on

any size paper up to 30 inch x 30 inch.

Coded Plots: Symbols-up to 12 distinct symbols (average

selection time 0.33 seconds) ; Numeric point identification.

PLOTTING ACCURACY (quoted as maximum errors)

Analog Plotter: 0.015 inches

Data Conversion: within 4 counts

Line Segment Conformity: 0.015 inches

PHYSICAL DESCRIPTION

Tape Reader and

Console X-Y Plotter

Width (overall) 42" 46"

Depth (overall) 32" 46 1/2"

Height 75 1/4" 41 1/2"

Weight (uncrated) 1212 lbs. 660 lbs.

Power-Requires 30 amp, 115V, 60 cycle (single phase)

service. (50 cycle model available on special order)

PLOTTING SPEEDS

Point Plots: Magnetic Tape (at 1/8 inch spacing) at least

350 ppm

Punched Cards:

Serial-fed-nominally 75 ppm

Parallel-fed-nominally 100 ppm

Punched Tape- nominally 300 ppm

Line Plot: Magnetic Tape: (depends upon setting of

Max. Point Displacement switch)

1/8 inch-540 lines/min

1/4 inch-306 lines/min

1/2 inch-144 lines/min

1 inch-114 lines/min

2 inch- 90 lines /min

5 inch- 42 lines/min

Punched Cards

Serial-fed-maximum 75 lines/min

Parallel-fed-maximum 100 lines/min

Punched Tape

maximum 300 lines/min

Coded Plots (1/2 inch spacing):

Magnetic Tape-at least 180 ppm

Punched Cards

Serial-fed-75 ppm

Parallel-fed-100 ppm

Punched Tape-180 ppm

Free Running Mode-up to 4500 ppm

(Data points are read at 75 inches per second

tape speed without stopping in the record gaps)

* Wide line (up to 1/16 inch) pens are available

** Other formats available on special order

(All equipment specifications contained herein are subject to change)

| BRL 1964, HYDAC 2000, starting page 0139

|

ACCURACY AND RELIABILITY

The accuracy of the analog plotter is 0.015 inches;

conversion of the digital data is within 4 counts,

giving an overall plotting precision very close to

the width of the line drawn. High stability, wirewound

resistors and silicon diodes are located in a

thermostatically controlled oven to give extra protection

against changes in environmental temperature.

Analog operational amplifiers are chopper stabilized

and, except for the tape transport unit, all circuitry

is transistorized for greater reliability.

20,000 COUNT INPUT DATA RANGE

The DATAPLOTTER plots up to 4-digit decimal numbers

of either sign, making its range effectively 20,000

counts or +9999 to -9999. Front panel controls are

provided to permit plotting 1, 2, 3, or 4 digit numbers

as desired. Scale and origin controls allow the plot

to be compressed or expanded from 1/3 of full scale

to more than 10 times full scale and to move the data

origin to a point either on or off the plotting

surface up to 4 board widths, depending on the scale used.

THREE PLOTTING MODES

Two types of plots may be made with the standard

DATAPLOTTER: (a) Point Plots in which each set of X-Y

coordinates are recorded as a point, and (b) Line

Plots in which successive X-Y points are connected by

straight lines. As an optional feature the system

may be supplied with equipment to provide Symbol

Plots, either as one of 12 automatically selected

symbols or with numeric identification of points. The

VARIPLOTTER may also be equipped with a second

plotting arm for additional plotting versatility. When

the second arm is equipped with a symbol printer

both pen or symbol plots can be obtained by the

selection of the proper arm.

PARITY CHECK

Lateral parity check is maintained on selected

words to minimize the chances of error when data is

being plotted from magnetic tape. By placing the

Parity Action switch on the Control Panel in the

"Reject" position, the DATAPLOTTER automatically

rejects questionable data and continues plotting. With

this switch in the "Stop" position, faulty data

causes the DATAPLOTTER to cease all operations so that the

operator can examine the nature of the error and take

appropriate action. The operator may decide to

manually reject the data or to correct it by entering

correct information with the Manual Data Entry

Keyboard. After either of these actions are taken,

the plotter will continue to plot subsequent data.

MAINTENANCE

Trouble-shooting and maintenance are easily

accomplished on the Series 3440 DATAPLOTTER.

All triggers and counters in the system are monitored

by visual indicators. The keyboard may be used to

simulate the tape. In this mode all data detection,

control and counting circuitry are utilized. All

digital logic and control printed circuit cards are mounted

on rolling drawers for easy accessibility. Each of these

cards has color-coded phone jacks on its edge which

allow safe monitoring of the output of all active

elements on the card. In addition, a Test Panel is

provided which contains a selector switch for

monitoring any of the system power supplies with a self-

contained voltmeter, and balance potentiometers for

balancing the operational amplifiers.

OPTIONAL EQUIPMENT

Optional equipment is available for increasing the

plotting versatility of the Series 3440 DATAPLOTTER. This

includes printing facilities for symbol or numeric

identification of plotted data, automatic incremental

advance, paper roll mechanism and others.

SPECIAL MODELS

Variations of the Series 3440 DATAPLOTTER can be

provided on special order to accept magnetic tapes

from other digital computers. A VARIPLOTTER with a

45" x 58" plotting surface is also available on special

order.

Magnetic Tape Format Definitions

Character-consists of a group of bits placed in each

of the seven channels on the tape.

Record-a sequence of characters along the tape.

File-a sequence of records along the tape.

DIGITAL TAPE TRANSPORT

The tape transport used with the 3440 DATAPLOTTER

is the Ampex FR400, which is designed for reading

tape prepared by IBM 650, 704, 705, 709, 7070, 7090,

1401, 1620, and CDC 160 and 1604 Computers. It is

equipped with hubs for mounting standard IBM or NARTB

tape reels using % inch wide tape. The tape is

read at a speed of 75 inches per second with a seven-channel

reading head to fit the dimensions of the

recorded data. Manual controls are provided for controlling

the tape reader in addition to the

automatic controls that are required to carry out the automatic

plotting operations. Brakes are provided

to automatically stop the tape in event of tape breakage or

failure of AC power. Optionally available

are stop devices which sense the IBM end of the tape foil markers.

WORD & CHAR. SELECTION. A record is first divided into

words of arbitrary size (from 2 to 12 characters)