Return to A Short Biography

- The role of the GE-225 and GE Datanet-30 in Dartmouth Basic - the original BASIC - starts at 12 minutes

- Arnold Spielberg, designer of the GE 225, was still alive and coherent at age 102, died Aug 2020 - local copy

- Dec 2019 - a few pages of a biography of Jim Haynes, another ex-GEer, after I left ...

- 2005 Mini GE-Reunion near Silicon Valley ;-))

- G.E. ERMA "Manufacturing Competence"

- A GE-225 computer is found.

- A GE-210 promotional movie

- A fake GE sexual harrassment video

- A history of the start of G.E. Computer Division - George Snively

- Another history by McGee - start at page 73, a comment about upper management page 77.

- Serious articles about GE Computers

General Electric Computer Department

from the bottom up

1961 through 1965

by Ed Thelen

Updates

General Electric Computer Department. - I was there January 1961 to January 1966

What promise!! - what happened??

Contents:

|

Warning - This monologue/tirade of G.E. sounds like a crotchety old man

discussing archaic computing equipment. Well, I sounded the same

when "IBM cards" were in and I was a new daddy instead of a grandpop.

In the glory days of computing - before the current standardization on the Intel 80486 architecture and Microsoft Windows - life was interesting. Any company that wanted a stock price surge announced it was getting into the computer business, hired a computer architect and some engineers that wanted to do something different, produced a computer that functioned, provided some EOM peripherals, sold a few systems, realized life was tough, and sold its computer operation for "pennies on the dollar". (And often the stock price jumped then also ;-)) Also - anyone who could spell the first four letters of "Computer" could get a good paying interesting job ;-)) Now you have to be able to talk "tail recursion", "stack frame", "memory leak" and other odd topics :-(( - and if you can't program in the language of the month, C++, JAVA, PYTHON, Lua ... , forget it. |

U.S. Computing Environment (ecology ;-) in 1960, in brief

|

1951,

March 31 | The first UNIVAC was delivered to the United States Census Bureau

*

*

Soon "UNIVAC" and "Computer"

were used interchangeably.

This jarred the data processing giant IBM, which regarded the Census Bureau as its private domain - Then Prudential Life ordered a UNIVAC and IBM began to scramble.

1953,

| April 7 IBM formally unveiled to the public the

701 Electronic Data Processing Machines.

*

*

| ... | ...

| 1960 | Now, there were *

| - Snow White (IBM) - (with a broad line of successful computing products) and - the Seven Dwarfs - SperryRandUNIVAC (having stumbled badly), General Electric, National Cash Register, RCA, Burroughs, SperryRandUnivac, Minneapolis Honeywell, and Bendix, Philco, Royal McBee, Monroe Calculating Co., and so on GE had the deepest pockets ( very handy ;-)) - but unknown to most, the lowest corporate commitment - The General Electric "Computer Division" was a boot-leg project |

From a high level perspective, "Top-Down", I suggest:

|

Rudderless Post Adolescent - me -

I had already:

|

I'm a new engineer - off to G.E.

|

I graduated from Milwaukee School of Engineering at the end of the fall

quarter 1960.

After the Army, I had worked for 6 months at Honeywell's Aero Division, Minneapolis,, and had an engineering job offer from them. However, I wanted to work for the Honeywell Computer Division. That division was interested, but couldn't offer me a job because Aero Division had given me a job offer and corporate policy ... blaa blaa blaa So I settled for my second choice, GE Computer Department, after talking with some folks at Johnson & Johnson of Racine Wisconsin who were maintaining the NCR-304 installed there. The NCR-304 was built under contract by GE Computer Department after GE had built the ERMA computers for Bank of America. The folks said that the water was fine, jump in :-)) Wife and I were almost dead broke at graduation. We had both worked to supplement the GI Bill. We had $100 from selling off much of our 2nd hand furniture at the end of college - but did not have enough money to rent a trailer and drive to Phoenix to the new job. I hated to ask my mother for the money - then a $200 graduation gift showed up from my Aunt Marion - and we (wife and 1st son Edward) rented a trailer and got from Milwaukee to Phoenix on that ;-)) (Gas was say $0.35/gallon and the tires were OK :-)) |

Phoenix & Computer School :-))

|

In Phoenix all I had to say was that I worked for G.E. and had instant credit everywhere.

I even rented a house using the good name of G.E. - no deposit, no 1st month, no nothing.

(This was before credit cards and that wonderful form of instant money.) As you can imagine, there wasn't much surplus left after the 1st pay check arrived. I was making $7,000 per year as a new engineer and in hog heaven! More than my father (an elected county official) had ever made!

I had been hired to do field maintenance on the GE-210

[promotional movie], the successor to the ERMA (above)

but now G.E. was advising that joining the new GE-225 effort was a good thing to do. So I did.

Our class of about 35 budding field engineers was given 6 months of very good schooling.

I was in tune with the principle instructor - everything he said was just the right thing

- at the right time - just like "good music". I soaked it up - delightedly.

Everything he said seemed to resonate in my head.

There was no Assembly Language assembler working when we started GE-225 class - we had to hand assemble our example and test programs ourselves. I was appalled - but was advised that a proper assembler would be available - real soon now - and in a month or so it did arrive. The six months went quickly, learning CPU, core memory, the inter-unit protocol and hardware, Anelex printer & GE Printer Controller, Ampex tape drives & GE Tape Controller, Elliott card reader - oh that sick puppy -, and were advised that the IBM 523 card punch leased from IBM was so reliable that there was no need for maintenance or a maintenance contract (true!). |

OK - what is a GE-225?

GE-225System Picture |

For computer affectionatos, the machine was all transistors, except for 2D21 thyratrons in the tape units.

The CPU had a 20 bit word, 8 K word (24 K character) memory with 21 microsecond cycle time with 3 core

based index registers.

(This is effectively 20,000 times slower than your PC and with about 10,000 times less memory.

And about 4,000 times more expensive to buy in adjusted dollars.) You could buy a 16 K word memory. More

system details at GE-225 Operator's Manual

and BRL publication,

4 page customer handout - 759 KByte .pdf,

GE-225 System Manual - CPB-98A

date 7/61 - 10.5 MByte .pdf

It, like most transistor computers was very reliable - maybe 1 transistor failed in two months. Typical GE-225 circuit cards It was a competitive mid-speed computer at the time. The killers were the poor to horrible peripherals.

|

GE-235System Picture Here is a

GE-235 System Manual.

| A GE-235 was a code and peripheral compatible three times faster re-implementation of the 225 with faster, more compact logic.

|

A real GE 225 exists :-))

| |

| There is a GE-2xx family price/performance chart in BitSavers in GE_Computer_History_1950s.pdf |

|

Documents Available on-line

"Scans" of many 225 documents exist on

Bit Savers ... GE-2xx

currently (Aug 2010) including

|

- CPB-247C_GE-200-SeriesOperationManual_Nov66.pdf

- CPB-252B_GE-225_PgmgRef_Jun66.pdf - CPB-252_GE-225_PgmrRef_Oct63.pdf - CPB-267_GE-235-SystemManual_1963.pdf - CPB-325A_AuxArithUnit_Mar65.pdf - CPB-1455_GE-200_Series_Time-Sharing_Operating_System_Ref_Sep67.pdf - GE_Time-Sharing_Activities_Jun67.pdf |

Also, Wilber Williams < travelmate800@live.com.au > has a collection at

http://wwcm.synology.me/scanned.html,

copied into here January 2023

ALL of the files were compressed by ILovePDF.com - medium compression

A comment on a G.E 2xx architectural "detail", by Grant Saviers

| My experience with a GE 215 or 205 (I forget the model number) was

interesting and indicative of GE's future in the

computer industry.

A graduate course I was taking required a project on the EE dept. GE/EAI hybrid computer. A really ugly concoction of scaling and programming issues. I'll never forget the sign hanging on the GE console: "Please do not divide by negative integers as it hangs the computer so badly you will need to do a power on/off reset." It then listed the code in FORTRAN II to check for negative divisors and to get the right sign on the result. That code needed to be inserted before every divide operation. Fortunately, neither GE nor hybrid computing went much further. Grant |

I propose that almost anyone can make a functional computer from commercially available parts. Heck, my "youngest" son made and demoed this. Well, OK - the really high end requires a genius like Seymour Cray. And OK, cost effectiveness and maintainability require some due diligence. But usually, bright normal people assemble existing tinker-toys and get the collection to work at an acceptable speed.

*HOWEVER* I also propose that creating effective, reliable, easy to use peripherals is not so easy nor so common.

Steven Spielberg's father designed the G.E. 225

|

March 2020

- and would you believe that Arnold Sielberg is 103 years old?

After all the rather negative comments I made above,

https://www.ge.com/reports/jurassic-hardware-steven-spielbergs-father-was-a-computing-pioneer/

These are some of the circuit cards whose sockets are

wired together (by Gardner Denver machines) to make the G.E. 225.

|

We're Off to Fix Computers ... :-))

|

Summer, 1961

OK - time to go to work :-)) Myself and two good friends were sent to G.E. Meter Department at Somersworth, New Hampshire to install and maintain their coming GE-225. Before leaving Phoenix, a personnel person handed out the expense forms and detailed their use. When we sent these forms back to Phoenix, we were told the forms were out of date and to fill out the new forms. Shades of Dilbert. !! How can Scott Adams get it so right? Very pregnant wife and I rented a charming little white painted house in a rural setting overlooking a lake / farm pond. AH - YES, I forgot to tell you that for some years I seemly arraigned the family life so that there would be a major move just before/after birth of a new baby. So Carl (our second child) was born as we were unloading the trucks and placing the equipment and connecting the cables and ... I wanted to be at the computer so that I would be aware, and not hopelessly left out of the computer scene. I drove the wife to the Dover, New Hampshire hospital then split for the computer installation. Heck, that was more interesting than standing around watch others chain smoke. For years there were family repercussions about my priorities !! For a few months we three good friend computer mechanics were doing the work of one, (even better than the government - no office politics).

AH - Air Conditioning for the computer. !! The GE-225 was a forced air cooled computer, air flowing from bottom to top, to get the heat out. An installation had two choices

Jim ... was not nearly so savvy :-(( One day he reported that the printer could barely advance paper. It turned out that he had gotten tired of the steel in the printer's electromagnetic friction clutch squealing, and had oiled it, causing the clutch to have almost zero torque :-(( - It is surprising how clean you have to get steel to get adequate friction. We had to clean the oil from that clutch several time. :-((

During that time, the summer of 1961, the district manager said I should go to the Anelex printer company in Boston to learn what I could of the manufacture and testing of the printer mechanisms GE was buying. Anelex, was a/the major maker of drum printers. GE designed the printer hammer drivers and control electronics for the printers GE supplied. http://www.ed-thelen.org/EarlyGE-Computers.html#Anelex I showed up and was given an Anelex escort - whose role was to keep me from doing exactly what I was supposed to do - spy on Anelex - . I'm sure that my district manager, and who ever else in GE, hoped for a more complete report than I was able to submit :-(( Even at that time the Anelex employees thought Anelex was in a death spiral - If you really screwed up, Anelex "kicked you up stairs" - there were reputed to be 23 "Senior Vice Presidents" at Anelex by then.

After a few months of the easy life, three friends doing the work of one, the district manager said that I should go to Allentown, PA to talk with a customer about to get a new GE-225 and see how site preparations were coming. So I took the family car to Air Products Inc. in Trexlertown, near Allentown (about 400 miles away) and met Carroll Claitor. Carroll wanted to know EVERYTHING, and I slowly realized that I was being interviewed. Apparently I passed. Returning to New Hampshire, I ran out of money, and arrived home smelly (no money for motel), hungry (no money for food), and only fumes in the gas tank. I did keep one dime for an emergency phone call if required. - again- this was before credit cards - It slowly dawned on me that I would be leaving our happy little group of field engineers and going it alone. I told the district manager that I wanted to stay in Dover, but the district manager said that was not an option. Charlie Winters was going to stay in Dover, I was going to Allentown, Pa., and Jim ? was going to Norfolk, VA. :-(( Another move - however, this time no late term pregnancy. - not enough time. |

Life on a General Electric Computer Department G.E. 225 site

Air Products, Trexlertown, PA, starting Fall 1961Part of this is being written in response to a request by Arvinder Singh Bawa, an Air Products employee, for images of GE-225 and Carroll Claitor, the manager of scientific computer at Air Products. I offer this little history of my minor part of the history of computing at Air Products, and Carroll Claitor.

The G.E. 225 computer site at Air Products Inc. in Trexlertown, PA was "typical" or "average" - although the Auxiliary Arithmetic Unit was not common. Air Products ordered:

Air Products had prepared a in a nice room with white raised floor and acoustic hanging ceiling. There were no glass walls for VIPs ;-)) The printer, printer controller, and card punch were in a side room also on raised floor with no door - for reduced noise for the operators. We unloaded the cabinets and boxes from a padded furniture van and took them up the freight elevator to the second floor - the engineering area. (The first floor was for business, and had an IBM 1401 system for business purposes.) A small room off the main room , with door, also on raised floor for convenience, contained the Field Engineer's supplies from G.E. (above) and work bench, various cabinets, shelves, ... The customer was responsible for supplying a desk and chair. I bolted the cabinets together, connected the interconnects and cables, and in a few days the computing system passed all its diagnostic tests and was running customer assemblies and production runs. (The customer had access to some East Coast G.E. computer site during the order and installation period to enable a rapid start of productive programs.) Emulating the LGP-30 computers being replaced

This customer, Carroll Claitor, readily accepted the fact that the machine was working as advertised - he was developing software and running production runs most of every day - and (after a visit by salesman Bill Peak) started paying rent or whatever. With in a week, the two cute LGP-30s that our system replaced were gone to no one knew where. Real world engineering computing

Remote diagnosis down to the slot

Also - Most folks didn't trust boards sent out from Phoenix.

Others noticed that my site (Air Products) had a higher uptime than most. (This was honest up-time, not some negotiated deal.) And folks were aware that the computational chief - Carroll Claitor - was no push over - Soon my supervisor (Bob Kessler) heard that my tape diagnostics were finding weakness that the regular tape tests did not find. If your tape system passed my tape servo test, customer runs were not likely to fail from a misadjusted tape servo damper. I handed out other exercise routines that helped test the incoming reels of tape from GE and locate bad spots before they interfered with customer runs. (GE was getting really poorly manufactured tape, "warranting" that it would work, and customers were having a lot of trouble with the stuff.) I got to travel our district (eastern Pennsylvania) to help install sites and help if there was trouble. Tit for Tat - Hot Stuff - well, maybe -

Hot Stuff, An Air Conditioning story

Hot Stuff, Temperature and Voltage Operating Margins, the techie view point

Hot Stuff, Card alignment and other Operating Margins

Who cares, its Christmas Break Headquarters types

The above type of story was repeated over and over again - There was the tape unit relay problem - Oh - my head hurts - The mis-used relay caused fits

Carroll Claitor stated on several occasions that he didn't understand how such a small organization (GE Computer had maybe 4,000 people) could be so bumbling and inept. Possibly Scott Adams says it best here Turf War vs the IBM 1401 operation downstairs

My impression of Carroll Claitor - Manager of Air Products Inc. Engineering Computing

Postscript:

|

A Year at Ellwood City

Starting Fall 1962a U.S.Steel town - made seamless drawn steel "tubes" - high quality pipes to you.

Iron pipes for houses are made by over-lapping sheet metal, and are weaker.

|

Ellwood City, an hour's drive north of Pittsburgh, PA sounds drab - it was -

We rented a house from the worst kind of electrical "do-it-yourselfer". We lived in reasonable fear that it would burn down or collapse during the year we lived there. Much of the wiring seemed to be extension cords. Then I and the new staff of programmers were given a tour of the tube works -

The reason U.S.Steel wanted our computer was to enable a U.S.Steel calling salesman, with prospective order, to determine a delivery schedule - which required determining the schedules of the draw benches with the dies and mandrels - Whew - got that ?? (see DataNet-15 below)

So - the machinery arrived, with the usual problems of installing it into the second story of some pre-World War I building with a barely adequate elevator and power. Then we found the air condition folks had decided that if the computer room air needed warming, they would blow live steam into the air stream - that does indeed work if you are steel, not humans trying to handle cards that warp on sudden humidity changes. Life was interesting :-|

My life was OK, I made some changes to reduce the audible noise from the tapes, and electrical noise from the fancy paper tape reader/punch unit.

The programmers and operators had to learn to tenderly operate the Elliot Card Reader (it tended to shuffle cards). The programmers were late and getting later, the people who were supposed to teach them steel draw scheduling (and later be fired?) were none too happy either. The whole place and all the steel people seemed old, tired, out of date, gray, sad, ... The only excitement was when the hard driving, unpleasant, lead programmer's wife committed suicide.

An ex-Phoenix classmate, Bob House, had his hands full with the GE bank system at the Pittsburgh Nation Bank. He had more mag tape units, mag tape usage, and at least three big high speed document handlers. I seemed to be there, visiting/helping him and his crew almost weekly.

My goodness, I did get around !! While in Ellwood City:

Added to the usual site repair and maintenance load was the rumor that disks were indeed beginning to "crash" - the flying heads would quit flying and grind off the iron oxide recording material of the disks. Soon the head itself would be destroyed.

Tape test and diagnostic programs, which I had written while in Allentown, PA were being passed around Eastern Region to help keep the troublesome tape system running better. The official test programs from Phoenix were not stringent enough. The authors had not faced real field problems.

I was getting tired of working in the field for GE - It was great for challenges, but made an absolute

mess of family life. I started bitching at my boss and sending resumes.

Then I got a phone call from Phoenix - would I like to work there?? I asked about getting clearance from my boss in Pittsburgh. The caller said that would be no problem, my Pittsburgh boss really didn't have a say in the matter. I was so tired of Ellwood city and GE Field Service that I probably accepted right there, before checking with the wife. Maybe part of the motivation was to find and fire up the headquarters slugs. I had built up two years of resentment and irritation!! The moving company was contacted and a replacement Field Engineer showed up. The last day I was there, the disk system crashed, horribly. We came in and there was iron oxide streaked in horizontal stripes across the windows of the disk system housing. Fortunately the customer was yet depending on our system for doing business. They were running their scheduling in parallel - using both humans and computer - comparing the results. - I didn't stay to help fix/replace the disk - other people were coming. I was out of there. !!! |

And 2.5 Years in Phoenix

HQ of GE Computer Departmentstarting Summer 1963 - apparently just after Arnold Spielberg left - I was unaware him until years later

|

OK - I went to Phoenix, Head Quarters of GE Computer,

after fixing and programming GE-225s for about 2.5 years - into the "Test and Diagnostics Software" group under Bob Decker.

As someone from the field, with considerable knowledge and a few hard knocks,

I was made welcome.

I went about (on my own time) looking for the knuckle heads that gave such shabby support to those of us in the field. Well - I was like a bull in a bull ring - really out of my element and relatively powerless against the existing forces who had seen and worked with irritated bulls before. Soon I was minding my own business. :-(( Life was good, the work was challenging and fun - and I was good at it. My boss and I got along just fine - we and our wives "double dated" quite a bit :-)) As Jackie Gleason was saying on TV "How Sweet It Is !!"

- Badges ;-))

From small acorns mighty oaks grow :-|

So - how to tell a personal adventure without booooring you to tears or turn-off

|

|

G.E. 225 peripherals - listed in order of crappyness

- one = worst :-((G.E. Computer Department was trying to sneak into the general purpose computer business - and it showed!

1. The Elliott Card Reader/Shuffler

2. The tape drives were from Ampex.

3. Decca tape drives were imported from England.

4. Early Disk drives

5. Printers from Anelex

6. High Speed Card Reader

7. G.E. Printer

The Document Handler for handling checks was OK. Actually wonderful compared with the other peripherals.

The IBM 523 Card Punch just plain worked !!

The Paper Tape Punch mechanism was from Teletype Corp. never heard of a failure.As I was leaving, G.E. tried to make/market a head contact disk, plated with rhodium which was to provide lubrication for the contacting head, that was supposed to be a break-through - well, it just cost G.E. another black eye, lost time, lost money, lost customers, ...

- The Elliott Card Reader/Shuffler - the shuffling was unintended !! 400 cards per minute

The Elliot Card Reader/Shuffler

click to enlargeA sharper image

from Wilber WilliamsAnother picture and discussion.

(image from http://www.retrobeep.com/computers/elliott/elliottPeripherals.htm ) For the first two years, the only card reader option for G.E. 225 was the world's second worst card reader - from Elliott Brothers in England (Was there was a worse card reader? open to suggestions). After reading, the cards were ejected into the top of the output hopper (on the left) where they fell to the bottom for manual removal. If the cards were slightly warped you could get a shuffle, and/or a card jam, in the output hopper, and the cards would be out of order for the next operation or pass. There were other serious problems also - like filling the input hopper and emptying the output hopper and mechanical problems, but the above took the cake.

G.E. added a thin piece of springy sheet metal about 3/4 inch x 6 inches to the output slot area, extending over into the output hopper on the left of the card reader, to try to deflect the cards down in good order. There was a little screw adjustment to position the springy metal to try increase its effectiveness. If you heard cards hitting each other or there was a card shuffle, you were advised to tweak the adjustment again.

Different decks required different adjustments -

And occasionally, the back end of the leading card would be hit by the front end of the following card, flipping the leading card over or causing an output hopper jam with cards in all orientations pressing up on the output hopper finger.This machine was a REALLY high maintenance item

To help keep mine going, I disassembled it every other weekend and repacked the bearings of the rollers that moved the cards with thick axle grease - which seemed to give sufficient damping of the card moving system for more reliable operation - like not getting mixed up on which column it was reading. - There were two methods of determining which column of the card was being read by the photo cells. The first method was used for the columns near the leading (left) edge of the card, while the card was being pushed by a little pusher arm and before it reached the output rollers. There were slots in the arm that indicated the position of the pusher arm, and hopefully the position of the card - but if there was not enough grease to damp things, the play in the pusher arm would whack the card and the card would bounce off the leading edge and an earlier column (or part of a column) was being read than indicated by the pusher arm slots.

The second method was a chopper wheel on the shaft of an output roller. Card column determination was transferred to a counter of the chopper wheel. Dust could collect in the slotted aluminum disk chopper wheel and confuse the column counter - regular cleaning helped reduce this problem

There was a check for end of card - if the end of card (all photocells lit) was too early or too late a card read alarm triggered. This check worked fairly well. You of course needed to make programs that could stop, let the operator take the card out of the output hopper, place it at the start of the remaining deck, and signal the program to re-read the last card.

This machine was easy to despise!!

OH - good grief - I forgot - the only safe way to reload the input hopper or remove cards was to depress the HALT switch on the front panel, then when done with those chores, depress the START button. But some people recommended lowering the REPEAT INSTRUCTION switch to do card manipulations, then raise the switch to continue. This caused havoc to the results if there was an arithmetic instruction going at that time !!

On the plus side, the Elliott card reader was evidently cheeep and not too bad if you only wanted to read one card. (Agreement)

LaFarr Stuart claims the RCA card reader was worse - Who can tell? LaFarr had worked with IBM equipment and was hired into RCA as an expert. One day the RCA Computer Chief Engineer (with a background in communications) called LaFarr in and asked him what an acceptable error rate was for a card reader - how many errors per thousand cards. LaFarr said that no error was acceptable. The Chief Engineer thought LaFarr did not understand the question. LaFarr proposes the Chief Engineer did not understand the problem. You may contact LaFarr via http://www.zyvra.org/lafarr/.

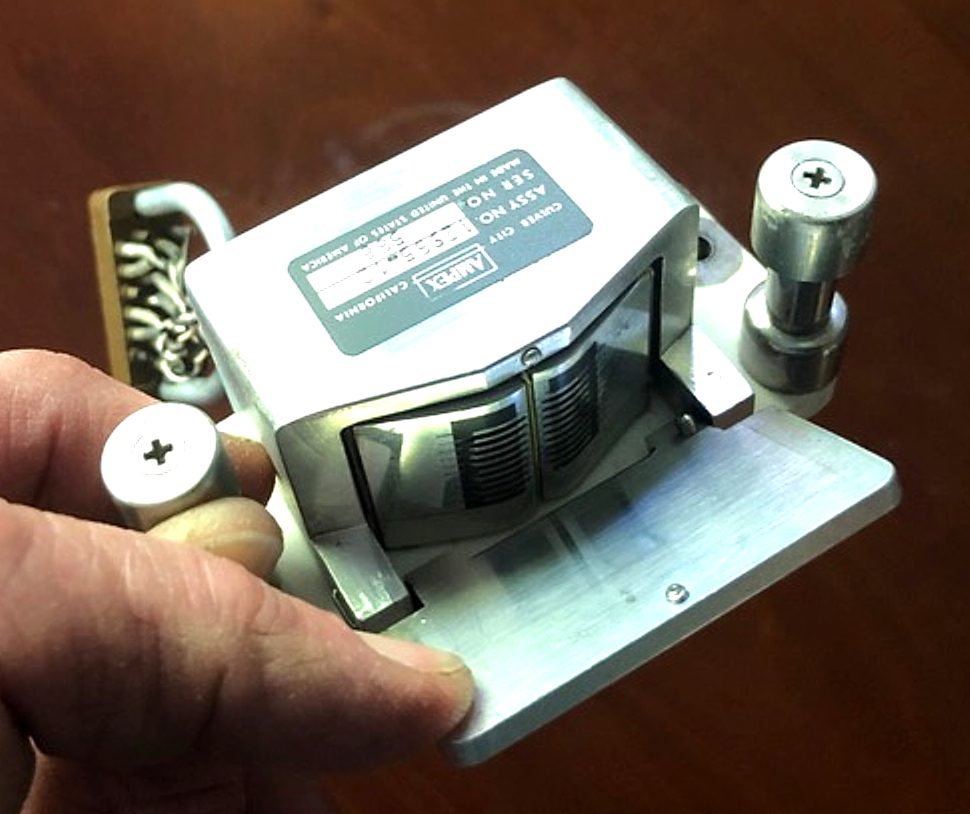

- The tape drives were from Ampex. Rewritten and extended again - July 2007, October 2010

Earliest drives, without pucker pockets

Early Ampex Read/Write head,

note steel tape guides :-(

Photo by Robert Garner,

of his equipment.

This is a video of a similar type of drive. Under conditions of many rapid starts and stops, things were more dynamic.

When the load handle is pulled, the sense arms go to positions of easy tape threading.

detailed pictures of

AMPEX TM-4 Tape Transports

as used on the ICT 1301, Kent, England www.ict1301.co.ukOriginally designed for light duty instrumentation recording service - they required a great deal of maintenance to keep serviceable in heavy duty business applications - such as sorts that can take hours of steady tape I/O - maybe 10 records/blocks per second - each record/block requiring a start and a stop - . One of the early symptoms that we were dealing with a light duty machine was the screw threads of the knobs that the operator twisted to mount a tape on the center spindle. After about 3 months of business use, with lots of tape mounting and unmounting, the threads wore and began stripping - making the tape drive unusable until a new nut in the center shaft, and new twist knob was installed. Soon a retrofit arrived, replacing the thread operation with a more robust levered handle. Lots of retrofits trying to convert a light duty easily aged drive to a more robust, low maintenance business data processing drive.

Ampex didn't seem concerned that iron oxide is abrasive - the side tape guides were steel. After twenty to thirty hours of tape movement, the magnetic oxide on the magnetic tape cut grooves into the sides of the tape guides. The abraded groves shredded the sides of the tape.

- Retrofit #1 was to permit the sides of the steel tape guides to rotate, hopefully evening the wear - didn't work as advertised.

- Retrofit #2 replaced the sides of the tape guides with ceramic. That seemed to work for a while - but then long black threads of (I guess) melted/recooled mag tape began to plague folks - but I was leaving for a Headquarters software job - good luck folks!!

Other quirks were, instead of tape vacuum columns (like IBM patented) these drives used vacuum "pucker pockets" to buffer the sudden starts and stops of the tape. The vacuum for the pucker pockets came from regular vacuum cleaner motors.

- The vacuum cleaner motors were *NOISY*. There was no sound damping in the drive area - so being near four loaded tape units was like standing next to four vacuum cleaners - fatiguing!!

Many people (including myself at both sites) bought extra vacuum cleaner hose and mounted the howling motors under the raised floor, which helped a lot. One fire marshal worried about motors under the raised floor, but I ignored his comment and he didn't press the point.

- Each pucker pocket had slot to permit the vacuum action to work. These slots were very noisy as the air rushed in to fill the vacuum. Fortunately they were mounted in front of the drive main plate so the sound was largely muffled by the transparent plastic door.

- The brushes on these motors lasted maybe 500 hours, then would start to arc destroying the commutator and causing the drive to fail - hard - like replace the vacuum motor. Of course you should add checking the length of the brushes to your monthly inspection - but there went another 15 minutes per tape drive.

OH - YES :-| The tape drives were manufactured in temperate California, and shipped from temperate Arizona. The hardened glass of the pucker pockets was epoxied to steel hinges so the glass could be swung out for cleaning.

- Unfortunately, the steel and the glass have quite different temperature coefficients of expansion - and if you received a system in a northern winter, the glass pucker pocket covers were usually cracked, and you had to send back to Phoenix for replacements.

- If the weather stayed cold, the replacements also cracked in shipment.

- So some regional CE or salesman would fly to Phoenix to hand carry a supply back to the cold region - say Wisconsin or Pennsylvania.

Oh - how can I forget - tape drive head alignment -

- As delivered from GE Phoenix, the heads were often misaligned so much that tape written on one drive could not be read on another drive. One of the things the installation crew would have to do is at least make all the drives on the site interoperable. Preferably, a customer tape from say an IBM system would be used as a reference if the GE system had to exchange tapes with other system. What slop!!

Speaking of slop -

- The tape supplied by GE in mid 1963 was so contaminated (little white surface particles, maybe 1/3 mm, maybe 1 per 5 feet) that the field people were well advised to write the tape from end to end (ignoring errors) several times before the customer used it. That way the stray particles left over from the manufacturing process would be (mostly) scraped off by the retrofit tape cleaners (that looked like the shaver foils from an electric razor). *really* I imagine the only people happy with GE supplied tape were the GE bean counters -

I should have mentioned the tape packer arm - to try to solve the "cinch" problem. The different wraps of tape on a reel would sometimes slide over each other, creating sharp wrinkles at 90 degrees to the side of the tape. This crinkle or "cinch" would set in the plastic of the tape and create a little line of tape that couldn't be read later. Adding to the seriousness of the problem, about one in 2^7th cinched records would pass the hardware checking, but not contain all the data originally written.)

Years later I found that the IBM 729 tape drive we were competing with had the same problem. :-| Apparently this was a generic magnetic tape problem caused by torquing the reels.

I had forgotten why we were so busy -

Yet Another Tale :-(( - Our Test & Diagnostics group received a specification (and budget) from GE hardware engineering for a magnetic tape upgrade to 556 bits per inch (bpi) (the next higher density). The specification also included all new op codes for use when using 556 bpi rather than 200 bpi. We were appalled - all the user and GE programs would have to be recoded to use this next higher density :-(( (We were sure other manufacturers were at least more internally compatibile.) Then we started hearing that the "floor techs" (who made the systems work before shipment) were doing a "boot-leg" project, on their own time, to make the mag tape hardware controller also operate at 556 bpi - with out really major hardware and software changes ;-)) Eventually hardware engineering adopted the "floor techs" ideas for the new 2-density controller. :-|

See this GE manual, page 2, for the Model 690 with added switch to change between 200 bpi and 556 bpi (555.5 bpi).Also see Ian Upton

Reginald W Oldershaw, who later worked at Ampex, mentioned the following Ampex oriented web pages

- Ampex Virtual Museum and Mailing List

- Preliminary Guide to the Ampex Corporation Records, ca. 1944-1999 Online Archive of California, Stanford

- Later (on the GE-625) Decca tape drives were imported from England. They used a "scramble bin" instead of the tape columns that IBM used, or pucker pockets that Ampex used.

- But the tapes needed 25 foot leaders and trailers to properly fill the scramble bins -

instead of the usual industry standard 8 foot leaders and trailers. (Interesting compatibility problems with other machines - even other GE machines. Customers had to patch on 20 feet of tape onto the leader and trailer of any standard tape they wanted to use on the G.E. Decca tape drives. How could G.E. engineering "management" be so $%^&*( stupid ??)- If there was any fault, a *pulse* was emitted from any of a number of sources to a latch that lit the blue failure light and shut down operations. There was generally no way to determine where that fault pulse came from. C. T. Winter (RIP) tried to get peripheral engineering to make more user friendly electronics - Ha -

- The systems containing DECCA drives had much more than the usual tendency to stretch and break mag tape - I don't know if it was the English electronics or the added GE electronics. The GE hardware people claimed that the fault was the COBOL SORT, and convinced GE Phoenix management to have the software folks examine the sort generated by COBOL for situations which could cause commands to the tape controller to break tape - I kid you not!!

- (From the above point) Until GE Phoenix eventually hired an IBM guy (John Haanstra), management had little clue about the realities of data processing. Unfortunately John was killed in a private plane crash after a few months :-(( The GE mantra was that "a good manager can manage anything". Maybe if the product is as simple as a motor or a transformer or a light bulb - but in the complex conflicting arena of data processing, GE managers were only bean counters with no computer industry knowledge to keep them from silly blunders.

Eventually a new general manager (?Haanstra?) correctly called the DECCA drives "boat anchors" and consigned them to the appropriate place. I have no clue about what drives replaced the Ampex and DECCA drives -

- Early Disk drives - "35 million decimal digits" - M640A - "Mass Random Access Data Storage Unit"

- OK lots of folks had troubles, but I contend "we" likely had more trouble. As I was leaving the field for Headquarters, there was a team going from site to site with automobile polish to slick up the disk surfaces. Unfortunately, any extra polish tended to slowly build up on the flying heads, destroying their ability to fly. This cure was worse than the original problem. People running the current "Winchester" technology are totally spoiled!

And of course, GE had to make a cost improvement that caused a lot of grief for a few months.

Robert Ollerton has this 31 inch diameter disk which he was told was from a GE-225 system.

- Printers from Anelex

Two major problems:

- The usual vertical dispersion problem rather than IBM's less obvious horizontal dispersion problem.

- And the usual user hostile GE controller - If you ran out of paper, the printer controller would reset, destroying the next data line already sent to it. To get that lost line printed you had to re-run the job.

IBM went to the extra trouble of sensing out of paper *after* the last line on a form. The just completed form could be removed and the next form inserted just below the print hammers, and life was easy.

GE and most others sensed out of paper about 6 inches below the print hammers and life was tough.

Really tough when running say payroll, billing, etc. Where several boxes or more of expensive multipart forms were getting printed in one run - customers had to prepare the expected numbers of boxes of paper, tape the beginning and ends of the boxes together into a continuous stream, and start out. "Been there, done that"

Also see Ian Upton

And expensive, unused logic in the controller -

G.E. wanted the 225 to compete with the IBM 1401, which had a Format instruction primarily used for "check protection" - an example being:

"$******43.21"

another option being

"$$$$$$$43.21"

for the dollar amount

which used a programmer defined control field to format the above example.To compete with the IBM 1401, the GE 225 printer controller had a little control memory and considerable logic to do the equivalent formatting.

Unfortunately, G.E. COBOL did the formatting in software, ignoring this very complex printer controller feature. The expensive hardware logic was rarely if ever used by G.E. customers. The formatting logic was not tested by "diagnostic tests" used in the field.

- And the later High Speed Card Reader

- This reader actually worked quite well - but was hell on cards. The cards were separated by an air-blast to get individually vacuum picked, transported by speeding belt past photo cells for reading, then stopped in the output section by impacting (smashing) them into a block of steel. The result was that the cards got limp rather than retaining their stiffness - and after about three passes through the High Speed Card Reader you were well advised to reproduce the deck. A deck going through the GE High Speed Card Reader say ten times was guaranteed to give jams of one nature or other.

Years later I used a Control Data 504 High Speed Card Reader using the same principle - but with a block of plastic to stop the cards instead of a block of steel - and the cards lasted "forever".

In "fairness", the card handling technique was very similar to the quite successful Pitney-Bowles document handler (reads checks at banks) that GE used, then manufactured. BUT,

- the documents went through the machine only once per bank/distribution point

- were much thinner and not supposed to be stiff

- and were much lighter and I presume slowed a lot from friction in the output hoppers.

Customers came to hate many GE peripherals, and hardly ever selected GE computers more that once. As much as some folks hated IBM's high handed marketing and prices, at least their equipment worked well and was maintained well.

Customers were caught between the Devil (GE) and the Deep Blue Sea (IBM).

The Document Handler for handling checks was OK.

A video showing Potter document handlers attached to a GE-210 - starting at minute 5.

GE 12-Pocket Document HandlerThe 1200/minute G.E. "Document Handler" for handling bank checks was really quite good, could usually run all night with no problem. (Banks run their checks at night, after collecting from the branches, to get the processing done before about 5 AM to get them into "The Fed" - or face stiff fines !! The design was from Potter Instruments, and the first Document Handlers sold/leased by G.E. were from Potter. These worked quite well. G.E. had procured them under an agreement that if Potter couldn't make enough handlers, or other problems, G.E. could manufacture the handlers itself.

Indeed, soon G.E. was manufacturing the Potter design, with G.E. external sheet metal. We in the field suspected that the G.E. management had just screwed Potter. G.E. manufactured the handler controller (not shown) so that the customer could sort documents off-line.

There was a G.E. design flaw that demonstrated that the designers had no clue about field conditions. The large ventilation/cooling fan was under the unit, sucking air and floor dust into the handler. If there was a problem, and documents (checks) started flying around the room - or an operator dropped a tray of documents, the cooling fan would suck the documents into itself, shred them, and blow the shreds into the machinery. Field people quickly reversed the fan rotation to stop that effect !!

The succeeding generations of G.E. computers couldn't operate these machines well - and G.E., which had most of the U.S. banking business (more than even IBM) - abandoned the banking business - go figure -

The IBM 523 Card Punch was not known to fail.

from "the web" via Wilber WilliamsI was trained on the General Electric 225 computer system. (Actually the G.E. instructors did a great job.) This included the logic to drive an IBM 523 punch. The 523 had a big cable and connector to plug into the 225. We asked about learning the 523 internals, and were told "Don't worry, they just work." And they did - On site, I wanted to see how tough they were. We punched "binary decks" of machine code loadable programs with about 50% holes - So I punch a few "laced" cards, all 960 hole positions punched. The machines groaned a bit - but just kept on working.

Why the Krappy Peripherals?

- Introduction - BUSINESS Machines

- The real world of business data processing

- "Recommendations"

- The Lockheed Denver fiasco

|

I think Thomas J. Watson (IBM's long time CEO) got it right - in 1924

Computing-Tabulating-Recording Company (C-T-R) changed its name to INTERNATIONAL BUSINESS MACHINES (Robert Garner says "International Business Machines was the name of a CTR subsidiary in Canada the renaming folks adopted back in '24.") I think the "BUSINESS" in the name focused IBM people.

As a (mostly) outsider, I admired the focus of that name.

Business relies on RELIABLE machines, not something that the engineers and management got tired of playing with and shipped.

The above paragraph introduces "business computing", where there are hard deadlines.

Most non-IBM people just do not understand the business real time requirement -

Most non-IBM people just do not understand the business data integrity requirement -

On the other hand if a student or scientist sees a screwy result

The above student or scientific acceptance of delays or errors is unacceptable in a business environment!!

IBM customers paid "through the nose" for unusual up-time and accuracy.

For instance, if an operator makes a mistake and puts cards with holes in them into a 1401 card punch, the checking circuitry will detect faulty output (extra holes).

For instance, at the Philadelphia National Bank, which had a G.E. computing system,

customers would disappear from tape records. This is not regarded as a good thing !!!

|

The real world of business data processing

I know that our managers didn't know the real world of business computing. The only exception was

John Haanstra, hired from IBM, who died after a few months in a private plane crash. :-((

I think few computer manufacturers outside of IBM expected high reliability. If a scientific computational run, or the usual student run, crashes - OK - lets re-run it - a couple of minutes - no big problem.

In commercial data processing, payroll and other events *had* to be on time or

there were expensive, costly, embarrassing consequences.

|

|

HQ engineers/managers should occasionally visit the real world of customers !!

It is relatively easy to:

OK - I'm bigoted - I think managers and engineers ought to have "real world" experience. |

| Lockheed Denver - as many others - "had had it with IBM" - so they started buying from

GE as a more humble, economical computer vendor. :-))

They had purchased:

For what ever reason Lockheed Denver became REALLY irritated with GE

Phoenix reacted, sending all kinds of experts to rectify the complaints. Returning experts said they were well along resolving the problems - but -

Lockheed Denver threw out everything with a GE Computer Department logo -

The word gets out - the world is very small - |

Granted that G.E Computer Department was chronically short of money - so is everyone, even the U.S. congress (which spends to

buy votes).

Somehow, IBM seemed to get reliability right (with a few exceptions, like DataCell ;-))

| The above "Why" section thanks to pressure from Karsten Lemm, a reporter for "stern", a German news magazine, who was not satisfied with my answer to "why GE shipped krappy peripherals". |

And let's not forget "cost improvements"!!

- The disk heads that flew - off

- The power supply bolts that smoked

- The core memories that *sometimes* forgot

- Make one prototype (G.E. 625) and time share it for hardware and software development

The GE Computer Department was basically a bootleg operation - GE Headquarters had issued an edict that GE would *not* get into the general purpose computer business, which was exactly what GE Computer Department leadership was trying to do !!

The results were that GE Computer Department did *NOT* have the deep pockets of the GE Corporation - although many employees assumed and acted as though the pockets were very deep indeed. (Another story for much later.)

In any case, GE Computer Department was always strapped for cash, and tried to make up for it by emphasizing "Cost Improvements". OK, how can such a good idea go wrong? Well, make the proposed "improvements" without checking with designers or knowledgeable people !!

False (very expensive) cost improvements were the rule, not exception. The slightest quick check with designers could have prevented many/most of the disasters. Unfortunately the "cost improvement" program was badly administered. Groups were rated by the number and estimated dollar saving of "cost improvements" they made. If the group checked with a designer or competent person, the "cost improvement" might be shot down before being counted - so there was a negative reward for checking. :-((

Where to start in this sad list?

- The disk heads that flew - off

The big GE "hard drive" (# 4 above) had a brief, special trouble. New production units would work "reasonably" well for a while - "reasonably" for that era in history - then individual flying heads would break loose and reek horrible havoc - crash other heads, score disk media, ... Investigation revealed that the beryllium-copper flexible head supports were breaking - but that the beryllium had been cost improved out. The resulting copper shim stock fatigued and broke in a few months. (As any mechanically inclined person would have predicted.)

The resulting retrofit costs and loss of customer confidence were severe.

- The power supply bolts that smoked

Power supplies (like 50 pounds each in these good old daze) had bolts to conduct the output power. You connected the power wiring (like +6 volts) and ground to these 1/4 inch diameter bolts. Suddenly, the power supply bolts of new production power supplies were getting very hot. The phenolic back panels that the current conducting bolts went through discolored and weakened and caused bad smells.

Investigation revealed that the copper bolts that had been used to conduct the 20 or so amps of + 6 volts had been cost improved by substituting iron bolts from a hardware store instead. The iron, having much higher electrical resistance than copper, got hot and caused the problems.

It was impractical to field disassemble the power supplies to replace those iron bolts and discolored phenolic back panels. New power supplies were shipped to the GE sites, and the local field engineers had more work to do - like life wasn't full enough already. Those Maytag TV ads of Maytag repair people with nothing to do were not GE field engineers!!

- The core memories that *sometimes* forgot

Intermittent problems are the bane of any computer fixer's life. You suspect that a part is failing - but when you test it - it works just fine - until the customer uses it for a few days again. The DataNet-30 (a communications computer) was an 18 bit word machine, (18 expensive core planes) with out parity which would have needed another core plane and supporting circuits. However, GE core memories had been very reliable (the ERMA for the banking industry, and the 225 that I had helped maintain in the field) - so the parity checking was eliminated in this product.

Except - new production DataNet-30s were having *A LOT* of trouble in the field.

After a few months it was noted that memory diagnostics could run for days, then suddenly fail, then run just fine again. What could be causing this?

- The hardware folks thought it was the flaky software folks and their flaky software - and customers were allowed/encouraged to program the real-time communication machines in assembly language.

- The software folks figured the complicated hardware was flaky.

- GE programmers and field engineers were flying all over trying to correct the problems and pacify irate customers that refused to pay for "their" DataNet-30s that were not doing the job.

The internal GE "Core House" had cost improved the soldering of the wires between core planes by not twisting the wires before soldering - the wires were just pinched together then soldered. In the field, these soldered joins could fatigue and crack just slightly. Conducting adequately sometimes, and not sometimes. Parity checking would have instantly identified the extended problem as a memory failure - and any soldering expert would have vetoed a pinched/not twisted solder connection.

And the bean counters did not assign a cost to this whole fiasco either. - who could? - A very risky change ("anyone familiar with solder joints would veto the change) saved maybe a person-week and cost hundreds of thousands of dollars in transportation cash, payroll cash, programming and engineering distractions, replaced memories, lost revenue, lost referrals, increased "cost of sales", lost reputation, lost "good will".

- Make one prototype (G.E. 625) and time share it for hardware and software development

Save money not making a second prototype - and lose it on increased engineering labor costs and increased time to market. For better or worse, the basic design of the G.E. 625 series was imported from G.E. Schenectady (where it had been developed for a military contract?) As explained in Homer R. Oldfield's book Software had the prototype computer for 12 hours/day, and hardware had it the rest of the time. But when hardware got off the machine, it might or might not be working. Or it might be working except some instruction might not give correct status or something - anything. The result was that software was badly delayed, hardware and software fought (what else is new?), and hardware development badly delayed also. Who can say how much that decision to save a second prototype cost in blown engineering salaries and late time to market? The bean counters seem to think other people (engineers) are free when making decisions!! I love Dilbert!!

- Its getting late - more, many more, enough to bore, later - the list seemed endless but I forgot lots.

In summary - the GE Computer Department "Cost Improvement Program" had many high profile failures - due (I contend) to management ignorance, inattention and blunders. I cannot imagine that the successes out weighed the failures by a high ratio.

I imagine the bean counters counted the saved paper clips and re-used typewriter ribbons, and missed the more complicated, embarrassing costs - bean counters are paid to make management look good :-)) :-((

Long Live Dilbert!!

- How can Scott Adams get it (his cartoon strip) so right??

|

I figured G.E. would not continue to sustain its losses of hundreds of millions of dollars per year.

And I didn't want to be in Phoenix with a house to sell when G.E. closed its doors. So I quit to work on IBM's TSS effort at Mohansic Labs where some of my friends had gone. (Manny Lemas - where are you?) (Would you believe Manny saw this request - probably googling for his name - and responded :-)) That is a much happier, more interesting story from my viewpoint. :-))

Cheers Ed Thelen - ed at ed-thelen dot org :-)) November 14, 2005 - updated occasionally |

"Buy GE policy"

and a little story

|

After the GE Computer "Department" got started, word got circulated within General Electric to "Buy GE" which included

of course, Buy GE Computers.

Fortunately, or unfortunately for the GE Computer "Department", many General Electric divisions had "automated" early, with IBM. The GE divisions were already demanding and sophisticated customers. They were already using IBM computers as business machines and knew that computer equipment could be quite reliable. So when GE bought GE Computers, GE had high expectations of reliability. When it became evident that GE computing equipment was considerably, painfully less reliable than the previous IBM equipment:

And I presume that the many unhappy customers spread the word to other potential customers, making the work of sales even tougher.

|

G.E. Computer Department Marginalized by the IBM 360

|

Answers.com defines "Marginalized" as "To relegate or confine to a lower or outer limit or edge, as of social standing."

General Electric Computer Department started as a bootleg business in 1956 after winning a bid to build the ERMA

machines for Bank of America. I contend that IBM out thought and out performed the rest of the industry when they

announced the code compatible computer series called "360". This reduced their costs of sales, training, ... and

left most of their competitors largely in the dust. IBM took the large middle part of the computing world,

and unwilling left

the low end to say DEC (Digital Equipment Corporation) and the high end to Control Data Corporation.

The environment at the time was that computer manufacturers in general produced a number of (incompatible) product lines

to woo different types of customers. The largest manufacturer by far was IBM (International Business Machines) which

had probably the widest range of product lines - here are a few that are easy to remember:

So IBM had to provide documentation, manufacturing specifications, training, sales and technical support of various kinds, software of various kinds, ... to this wide range of machines. And of course, each product line had its protective management, sales force, ... And this practice was hard on customers who wanted to upgrade to newer, faster, ... machines. Very expensive to develop programs had to be recoded or recompiled and adapted to the different somewhat compatible or totally incompatible new machine. Operation manual re-written, ... much trauma.

The above provides an idea of the environment that the General Electric Computer Department was operating in - with

more or less success. And General Electric Computer Department USA had three product lines:

Actually the 400 line was supposed to provide a wide range of solutions but G.E. could not make a fast version of the 400 and so imported a non-compatible high end design from G.E. Military in Schenectady, N.Y., and made it into the 600 line. So - General Electric Computer Department was following the standard business practice, a number of incompatible product lines. I was working in the "Test and Diagnostic" group under Bob Decker, and we provided manufacturing and field test programs for the above US product lines. Lots of interesting work. Something always happening :-)) :-(( We of course got to know some of the 400 product line designers and engineers, who were very bent out of shape about the loss of their high end product to the new 600 product line. They felt that with sufficient push, their high end machine would be a winner. We heard of their dreams of the glories of a single code compatible line of computers and peripherals for all customers. But we in "Test and Diagnostics" had lots of fish to fry and didn't pay much attention to the complaints of some of the 400 line guys and their truncated dreams. Then one day in 1964 (must have been April 7th according to IBM) we heard that IBM had introduced their rumored new system, now called the "360". We were all curious, but had no details. That evening, while working late, I starting hearing strange wailing, and curses, and shouts, and pounding on desks - very unlike the usual engineering environment!! What was going on? - I went to see a furious friend. He had a thermofax (pre Xerox) copy of the 360 family of specifications - and he was hopping mad. IBM had announced a dream line of code compatible machines rather similar to the 400 line - but much wider in performance that the truncated 400 line!! And IBM had announced that in the future all of their machines would conform to the 360 "architecture" - and be code compatible. My friend was so mad he was almost crying - unlike Dilbert. And there were still shouts and moans of frustration from others going on all around - I had never heard/seen any thing like that before - nor since. I didn't think of it at the time - but a perceptive person would have recognized that the computer battle had taken a serious turn toward code compatible product lines - and poor G.E. missed the turn. Its sales force would have to continue to try to field customer questions about how to migrate their programs from say the 400 line to the 600 line. The obvious answer is "re-compile" but the customers knew that different environments and operating systems made another level of complexity. And if a customer had a 400 in one location and a 600 in another location - might as well been made by two different manufacturers. Not convenient for G.E. not convenient for the customer!! So poor G.E. was out maneuvered and had more sand thrown in its face. And IBM was doing record breaking business - people were placing orders for the 360 so they could sell their delivery date to someone in a hurry.

LaFarr Stuart - lafarr at zyvra dot org - says that IBM wanted a "second source" for its "360" and selected RCA (Radio Corporation of America) for that function. IBM provided RCA with design documents, concepts and facilities documents, and others early and made a considerable effort to assure that RCA seemed a viable alternative. RCA announced its product line largely mirroring IBM's product line - but RCA with its crummy peripherals and unsatisfactory/horrible reliability soon fell by the way side. Emerson Pugh says in his paper Technology Transfer (local copy) that the RCA Spectra 70 was a copy - and does not mention the idea of "second source" at all.

I bumped into code compatibility later at Control Data doing sales support to the government. IBM was offering a product line of military computers called the "System/4 Pi" - which was a militarized 360. (A circle of 360 degrees has four Pi radians - a unit of angular measure). In any case, customers could compile and debug large parts of the code for the "System/4 Pi" on their IBM 360s, and wanted to know if Control Data had any similar compatible capability between the CDC 6000 line and Control Data's military computers. We dodged and wiggled and squirmed, but our answers were unsatisfactory, and generally the prospects wandered off - presumably back to IBM. :-(( |

Blame Game??

- Who/what caused the failure of the GE Computer Department

A symptom would be that no one reordered from us. Exceptions

|

It has been about 30 years since the GE Computer Department disappeared into Honeywell,

and 40 years since I left - but still Department veterans meet - and soon start to discuss "What Happened?"

( August 2015, reunions seem to have stopped. ) But oddly the discussions are not finger pointing sessions - all groups seem to look inward, seem to feel guilty. They all point to successes of their group, but somehow that was not enough -

I have basically quit going to reunions as there seems nothing new, and the national reunions are dominated by sales and marketeers - who tend to look down on techies - a good salesperson can sell anything, who needs techies. In any case, I am very alone in blaming crappy peripherals as the basic reason that expenses were so high and there were so few repeat customers. It is like spitting up wind -

But then again, management is ultimately responsible for the crappy peripherals

Maybe the fundamental problem involved the Computer Department founders, who defied and tricked Corporate. A very good article - added July 2014

|

Early GE Time Sharing - a side view ;-))

Not yet checked by Don W Fry, Albuquerque, "Don Fry" < dwfry @ tritel . net > maybe the only other surviver of our group ??

also see Time Sharing History of Don Fry

|

There is a VERY interesting YouTube video on

'The Birth of BASIC - Dartmouth Time Sharing,

which reminded me that I had a view of Dartmouth Time Sharing too ;-))

After two and a half years fixing GE-225 systems, I was brought into the "Diagnostic Test" section at headquarters at Phoenix. (OK, I was fairly well known in the NorthEast, and a class mate friend had a friend ;-)) One of my first tasks was to gather/create tests for the DataNet-30 which was having severe reliability problems at the time. I had never seen a DataNet-30 (DN-30) before that. This was an 18 bit machine with a special macro instruction to check/input/output all of the up to 127 serial serial channels much more quickly than could be checked in a programmed loop. The programmed loop could be taken literally, the program input device for a DN-30 was a punched paper tape reader ;-)) The punched Mylar based paper tape could be fed from one waste basket to another to avoid knotting and tearing. There was a hand held wind_up machine based on a motorized paper eraser used by draftsmen. Then I heard that recent production DN-30 computers were sick - but that the early Dartmouth Time Sharing DN-30 was rock solid. ? What is Time Sharing ? So "Time Sharing" - the story I heard was that Jerry (Ezekiel) Weiner (Manager of GE Computer Advanced Systems) had been involved. "Jerry" had been apparently unconventional - When the Dartmouth Time Sharing system was on the GE factory floor for integration and testing, the night shift floor techs were suspected of swapping suspect boards and parts from their own systems with circuit boards in the Dartmouth system. "Jerry" reacted by wrapping thick chains around "his" Dartmouth bound system. The plant manager was called in and chastised "Jerry" for this unseemingly behavior. Several more senior people I knew claimed to be on good terms with "Jerry" had a strange tale - apparently on a Sunday "Jerry" had been called into the the GE plant (on Deer Valley road - now a shopping center). He was met by the General Manager and a security person - and told to clear out his things - today - now. My friends said that management was worried that "Jerry" was so popular and well thought of that he should not be fired when folks were around. Later, when GE wanted to commercialize the Dartmouth System, George Fraine, a friend was given the task of adapting the software to commercial purposes - different log-ins, ... And apparently the Dartmouth system occasionally lost a user program - fix that too !! After an extended struggle George found that the fixed size file allocation program had a weird bug. If a user program was almost at the 3,000 character maximum, and just the right number of characters were to be appended, the update overwrote part of the NEXT header, destroying access to that other innocent file. The DN-30 had three characters/word, and someone at Dartmouth had mis-coded one particular situation. At one of the time sharing conferences announcing GE's entry into Time Sharing, which I wasn't invited to, I was on speaking acquaintance level with half of the presenters. What a ego boost ;-)) Later I went to work on IBM's TSS effort.

My views on the often pooh-poohed BASIC

|

Mail Bag

from Jim Phillips - December 2005

|

Hello Ed

...

The day I walked in, the GE Installation people were finishing up. The customer had not signed for machine. As I walked into the room there was 4 or 5 people standing in front of the CP. They were pointing and laughing and talking about - guess what?- the Elliot Card Reader. If you think about it, the visual impact of the 225 and assorted peripherals is good. Or it was in 1963. But, the Elliot sitting up front in plain view destroys the image. It also invites questions. Like- what is it? Does it work? How can it read cards? How does the card get from there to there. Your kidding. First impressions- one is all you get. The WHOI Computer mgr was a good guy. He knew more about computers and the computer industry than we (GE) did. He had worked in computers for Lockeed in Glendale for a number of years. I walked up to intro myself as he was saying- and I will NEVER forget it- he said pointing at the Elliot, "GE can't be player in this industry if they think this is a card reader". Not a bad start, huh. Well to make the story short, I was there a year and the ONLY problem I had was the Elliot. The humidity (building was 30 feet from the Atlantic ocean) was a big problem. The scientist (users) would carry their object deck around in their back pocket. The WHOI Comp mgr understood, to a point. He and I became good friends. Drinking buddies even. We had many discussions at the Lee Side bar in Woods Hole. We concluded that the Elliot was a symbol of GE in the computer industry. A symbol that GE did not understand the industry or was GE being GE. Whatever. Over a beer at the Leeside my friend told me the story of how GE beat out IBM for the 3 yr lease. My boy had a grant from the National Science Foundation for a three yr lease and change to run computer center for same 3 years. IBM was the favorite, of course. The current installation at WHOI was a Bendix LPG?. I forget the sys IBM was going with (1440?). Anyway IBM was at $14,000 a month for 3 yr lease. The sys GE recommended (see above) was $14,000 a month. However after getting 8000 finance people from Phoenix involved, we said we would let them have same sys for $8000 a month. GE salesmen could not sell/lease computer without 8000 people from Phx finance, contracts adm, etc being involved. The Phoenix GE PEOPLE loved to get on airplanes and fly to anywhere to help "close the deal". So, we called it an Education discount. IBM said if they matched that price they would lose money. Hope I don't sound jaded. As you now I stayed with GE/Honeywell for quite a while. I grew up, married and raised a family while working for GE. But, I never became a GE PERSON. Now George Snively (sp) is a GE PERSON. And will be forever. I think you know what I mean. ... |

from Ian R Upton - Feb 2006

|

Ed,

Somehow I stumbled across your site and it's history of GE and the 200 line of computers. I commenced work on them in 1964 in Australia and certain aspects of the system are burnt into my memories for ever: The Elliot card reader, what a challenge to keep them going. The Ampex mag tapes. You buy some long hose and mount the vac cleaner fans under the floor to cut down the noise. I liked it when all the thyatrons fired and the tape was stretched or one lot fired on and then would not come off so you had 2400 feet of tape in the door. I got so involved with my tirade I forgot mag tape noise suppression. They were so loud that folks got fatigued. And ear plugs were probably not appropriate for the G.E. representative. The 1200 LPM printer and the rotten mechanism for keeping the ribbon aligned. Also the clutch mechanisms which slowly wore giving all sorts of problems. Other faults I forgot - the list gets so long that after a while you worry that no one will take you seriously. We had one system which suffered from "stress corrosion", something in the air from the air conditioning, the plating on the transistor legs and they way they were soldered. An engineer slammed the door on the printer controller one night and some transistors fell off (mainly the 11g11 board), Woops you just had to touch them and the leads broke so we replaced thousands of them over the entire system, Unlike you I stuck with GE, Honeywell, Honeywell-Bull, Bull, Wang and Getronics before they laid me off about 6 years ago. Worked in Australia, New Zealand, the USA (Phoenix mostly), France and Japan. Worked as a hardware and software person on the GE 225, 265, GE400, GE600/6000/DPS90, GE58, GE 140, 115. Do you have any old prints or other documents. A number of us are beginning to help Al Kossow expand his already ENORMOUS web site. We can scan documents here and send them back - or we are thinking of having remote Kinko outlets scan the documents to .tif files to CDROM. Still working in the business but it is not quite the same as the heroic early days of computing, Regards Ian Upton. PS: Somewhere you mention getting $145 per week, around the same time I was getting $60-70 (Australian) per week. |

I am associated with a restoration of an old IBM 1401 computing system -

http://ibm-1401.info/index.html

and we got one of our IBM 729 tape drives working (mostly), at least enough

to load/forward/rewind tape.

There were comments about the unfortunate noise the drive made when it

loaded tape into the buffer columns.

> Glad you like the noises! ;-) > > Robin thought the tape drive sound (the vacuum "fart" when the > tape loads) > sounded like an ER surgical procedure! ;-) >Indeed, the IBM 729 tape drive column suck in noise is a bit gross!! But at least it doesn't ruin your hearing.

I serviced G.E. computing equipment which was competing with IBM.

Our early tape drives were made by Ampex.

They were different from the IBM tape drives - avoid IBM patents??

The pucker pockets pulled in the tape, and had a slot on the side to provide variable tension The air being sucked into the slot made a loud whistling/shrieking noise. And you know how loud a vacuum cleaner motor is when it is housed in the vacuum cleaner. Well, these vacuum cleaner motors were in the open bolted onto the frame of the drive. And the typical G.E. Computer installation consisted of You could hardly hold a conversation near by!! Many maintenance people unbolted the motors from the frame and using longer hoses they purchased, placed the cursed things under the raised floor. The slot shriek was unpreventable - I soon got into software and a better life !! - that IBM tape drive farting suck-in sound is a small price to pay. Cheers --Ed Thelen |

Canadian Banks - July 2007

From Stan Heinz

- also see Pictures and more comments

|

Stan had said that his company, a bank, had re-ordered G.E. Computer Department equipment -

upgrading from a GE-225 to GE-415. This was the second re-order I had ever heard of -

and asked for more details :-))

I was with the Canadian Imperial Bank of Commerce in Canada. We ran IBM and GE (later Honeywell ) equipment across Canada. Montreal and Vancouver were using GE equipment. We had GE 225 with a 900 LPM printer, 6 200 Bit per inch-75 inch per second tape drives. This was back in 1963-1965. Regarding the cheque sorters we only had with the GE 225. Later when we went to the GE 415 we still had 2 sorters but different models and then added a third. The tape drives and printers were faster as well the printers being 1100 LPM models. Over the years we upgraded further, ending up with 3 GE 435's running DPS (Disk Programming System) and 3 sorters. By then we were running in-house On-Line Banking Systems with 2 GE Datanet 30 (GE 225) communications processors for the GE 435's and Olivetti Banking Terminals. For a short period We also had a Bull (GE 115). We ended our usage of GE equipment in 1976 when we started to convert our systems to IBM 370. I started in the Bank in branches for 1 year and then transferred to the Data Centre in Vancouver in 1964. I ended my tenure as Manager Computer Facilities when I resigned in June 1987. By the way, I don't think we ever tried to run more than two cheque sorters on-line at any one time and you are correct, the sorters ran off line much of the time to do general cheque sorting prior to shipping them back to the various bank branches. As I recall, the 435's were fast for their time at about 40,000 operations a second. I seem to recall a memory cycle time of under 4 micro-seconds on a 24 bit word with 4 BCD 6 bit bytes per word. ... Later and regards.................Stan

I've had a quick look and am amazed at the info provided. You brought back some vivid memories when I read some of your stuff on the GE 225.

Those were fun days!! By the way I seem to remember that an IBM 1401 could only do about 2000 operations (instructions?) per sec. I believe I have this info somewhere. Stan |

Mike Robinson Australia - Feb 2010

|

Hi Ed,

I worked on the second GE-225 installed in Australia in the early 1960s. The first was the installation at Queensland University, Brisbane, which you have referenced in your entertaining article about the quirky peripherals attached to the early 225s. The second installation was at Carlton and United Breweries in Melbourne, and I was a programmer at that site. Ian Upton, who commented on the Elliott card reader, was a maintenance engineer at the site. I remember him well. The third installation was the Snowy Mountains Hydro-Electric Authority, and the fourth site was the Bank of New South Wales in Sydney. I think that was the extent of 200-series sites. Subsequent GE machines in Australia were sourced from Machines Bull in France or Olivetti in Italy. A GE-600 was sold to the Australian Department of Defence in about 1968, but the sale was later abandoned on instructions from headquarters in Phoenix Arizona, much to IBM's delight. I was stationed in Phoenix in mid-1967 doing benchmarks on the 600 series for the Australian government, and vividly remember how easy it was to change a machine from a 615 configuration to a 635 configuration. The operator pulled a wire out of one socket and inserted it into another socket, and presto! the machine took off like a rocket. I recall seeing an experimental cathode ray tube connected to a machine on the factory floor in Phoenix. It was a precursor to today's monitors, but back then there was no software to drive this type of peripheral. I also recall the many evenings when we abandoned scheduled production runs because of the lightning storms that raged around Phoenix in the summer months. Australian General Electric had service bureaux in Melbourne and Sydney, from which the company serviced many important customers, including banks and government agencies. Both centres had document readers for processing checks. Ironically, all the banks that used the service bureaux bought IBM machines, and the Bank of New South Wales followed suit after the Honeywell merger.

Regards,

|

Paul Boisvert Somersworth N.H. - Feb 2010

|

Tremendously enjoyed your GE225 stories. I started programming these guys in GAP and sometimes in

"octal" via the front panel in a pinch.

Paul Boisvert |

Fred Beazer Virginia National Bank - Sept 2010

|

about nobody re-ordering GE computer equipment